In this weeks article Quantifying ferrite in duplex stainless steel with magnetism and searching for sigma (Part two of two), Ana Benz, chief engineer, IRISNDT; Brad Berglan, laboratory manager, Maverick Testing Laboratories, Inc.; William F. Newell, PE, PEng, IWE, vice president Engineering, EUROWELD; Charles W. Patrick, director of Technical Services, Maverick Testing Laboratories, Inc.; Glenn Roemer, materials engineer, IRISNDT; Ramon Solo, metallurgist, Maverick Testing Laboratories, Inc.; Elaine Thomas, director of Metallurgy, BRADKEN Tacoma, continue to explore how duplex stainless steels (SS) have a remarkable combination of high strength and exceptional corrosion resistance.

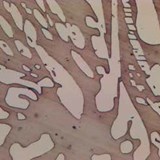

Cast Duplex SS is known in the foundry industry to have lower FERITSCOPE® readings when the heat treatment is faulty and sigma is present, the group explains. The missing ferrite percentage is replaced by less ferromagnetic sigma. Through these examinations, a CD7CuN 5 inch x 15 inch (126 mm x 381 mm x 381) test block was heat treated and purposely overheated to transform ferrite to sigma.

To read the full article, please email Catarina Muia at c.muia@kci-world.com for the PDF.