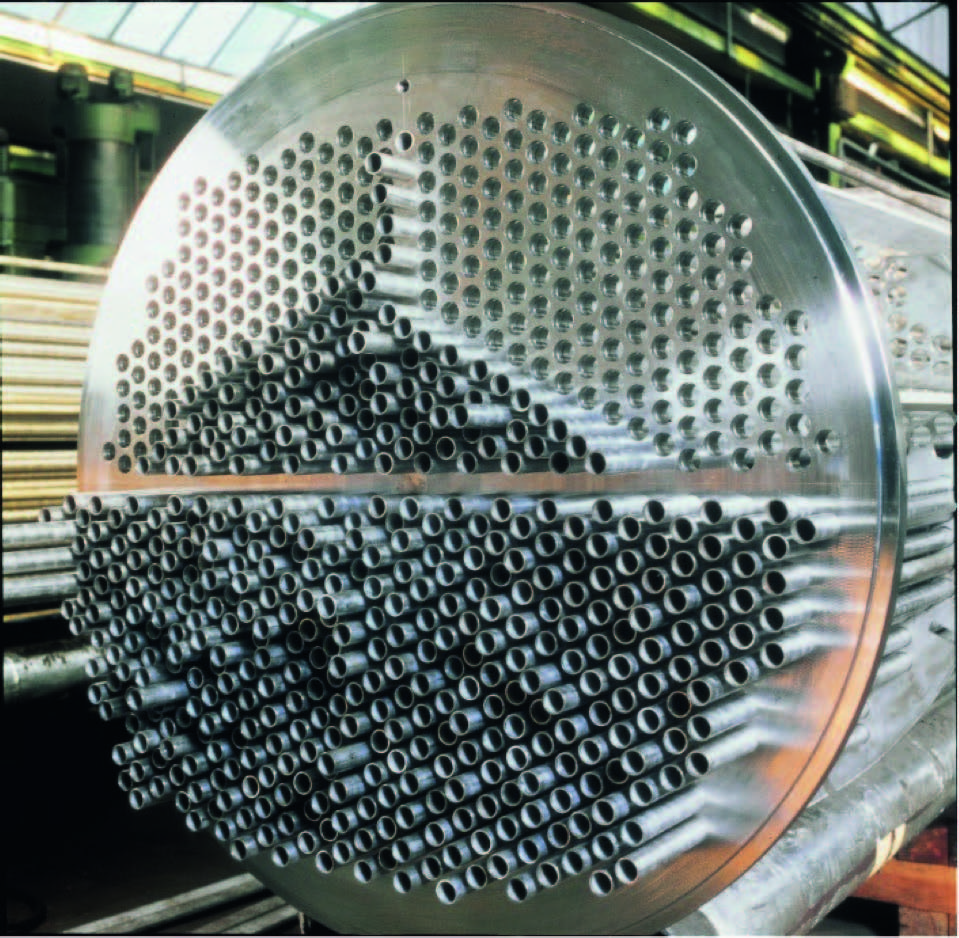

Stainless steels alloyed with a high percentage of Chromium, Nickel, and Molybdenum have been widely popular as a material in the construction of heat exchanger tubing (as well as pipes, fittings, plates, and more) for demanding and highly corrosive process conditions such as acids and salts, as well as operating in high temperatures. The two most used alloys in this segment are UNS N10276 and UNS N06022. Another alloy, UNS N06059, is gaining popularity as a material used in severe corrosive environments.