This article elaborates the need to discuss super austenitic stainless steels as an alternative to options mentioned below.

By Venkat Ramesh, Global Product Manager (Heat Exchanger tubing), and Shabareesh Nair, Director (Technical Marketing Asia), Tubacex Group

Introductory Background

High Nickel alloyed stainless steels are categorized as having Chromium + Nickel greater than 50%, and most of these alloys have Nickel greater than 30%. These materials have been used widely in petrochemical, chemical, refinery, and organic acid industries, due to their excellent overall corrosion resistance to various types of media and harsh environments involving high temperatures.

In recent months, there have been challenges faced by supply chain to procure these types of materials which have seen wide fluctuations in prices, and long lead-times. This also adds to costs and budgets of major projects involving such materials, and sometimes leads to material selection changes to inferior alloys. This has resulted in an increase in OPEX cost and unplanned shutdowns in various applications.

Austenitic stainless steels, on other hand, are not subjected to such high prices and lead times, but in applications involving severe corrosion, they are not suitable for use, and if used will have very short life.

Duplex steels have been used widely over past years as an alternative to austenitic steels, due to its superior corrosion resistance under certain conditions. But, the major drawback has been its limited temperature zone within which equipment can be operated. Additionally, there are also issues with stress relieving heat treatment post U-bending.

Description

Super austenitic stainless steels, by definition, are steel grades with PREN number (as calculated by formula PREN = % Cr+ 3.3 x % Mo+ 16 x %N) greater than 35. These can also be classified as Cr-Ni-Mo steels, or Cr-Ni-Mo-Cu steels, having most Chromium content between 17 and 25%, nickel between 14 and 25%, and Molybdenum between 3 and 7%. Many of these grades are also alloyed with nitrogen to further increase corrosion resistance and strength. Some grades are alloyed with copper to increase resistance to certain acids. It also has fully austenitic grain structure in annealed condition, good cold and hot workability, and is easy to weld.

Some of the grades this paper elaborates on in detail are super austenitic, mentioned in Table 1.

Wet Corrosion Properties

Pitting Corrosion

Pitting is localized corrosion in a pattern of rat holes penetrating through the tube wall. The initializing of pitting depends on several factors, such as presence corrosive environment (e.g., Halides-Chlorides, Bromides, and Fluorides), temperature, and most importantly, the defects and weakness of the steel passive protective layer. Once pitting initiates, the propagation is much faster. Presence of higher % of Chromium in stainless steels helps in pitting corrosion resistance as forms a strong passive layer of Chrome oxide on surface. Similarly, a high % of Molybdenum helps in pitting resistance as it helps lowering the pit growth rate. Higher Nitrogen content in steel is useful to fight pitting corrosion as it helps in neutralizing the acidic corrosive solution. PREN, or pitting resistance equivalent, is used as a rule-of-thumb for material selection in these conditions, which is % Cr + 3.3 % Mo + 16% N (in case of austenitic, duplex, and super austenitic steels).

As can be seen in Table 2, super austenitic stainless steels have PREN more than 27, which is higher than standard austenitic grades and some of these grades have PREN higher than duplex (35) and super duplex steels (42).

Critical pitting temperature (CPT) is calculated by ASTM G 48 Method A corrosion test, which involves the exposure of the materials in a 6 wt % ferrite chloride solution for test durations of 72 hours (typically 24 hours). This is temperature at which pitting corrosion may start. The CPT of materials which is a direct proportion of their PREN is good indication of how good these materials are against pitting corrosion.

When it comes to chloride induced pitting corrosion, super austenitic performs much better than standard austenitic steels, and equally or better than duplex steels.

Stress Corrosion Cracking

Stress corrosion cracking (SCC) is the cracking induced from the combined influence of tensile stress and a corrosive environment. The impact of SCC on a material usually falls between dry cracking and the fatigue threshold of that material. The required tensile stresses may be in the form of directly applied stresses or in the form of residual stresses.

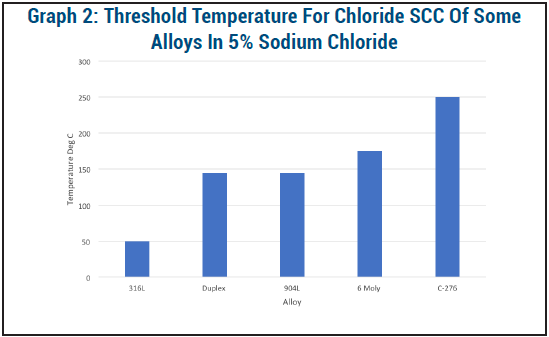

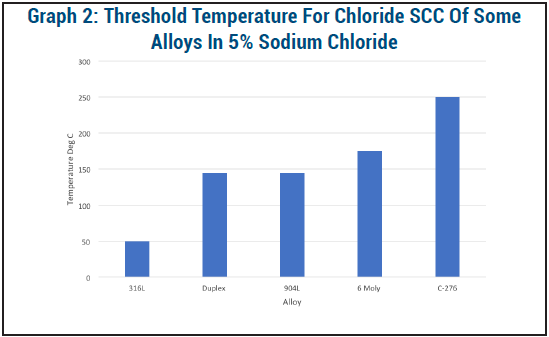

Chloride stress-corrosion cracking (CSCC) is one of the most serious forms of localized corrosion. Higher temperatures and reduced pH will increase the probability of CSCC. It has been determined that alloys become more resistant to SCC as the nickel content increases above 12%, and the molybdenum content rises above 3%. SSC of super austenitic stainless steel is superior to the standard 300 series austenitic stainless steels, and some duplex stainless steels.

The alloys 6 Moly, Alloy 926, and N08367, exhibit a good resistance to chloride induced stress corrosion cracking, as seen in Graph 2. It improves from 6 moly to Alloy 926 to Alloy 08367. They are immune to SCC up to boiling temperatures when in the presence of chlorides.

The grade N08926 has more than 20% Nickel, and more than 2% Molybdenum, which leads to improved SCC as compared to standard austenitic steels.

Reducing and Oxidizing Acids

Most of super austenitic stainless steels are copper alloyed, which gives it good resistance to reducing and non-oxidizing acids, such as sulfuric and phosphoric acids. It is also seen that high Chromium % gives a strong passive layer, and improves corrosion resistance to sulfuric and phosphoric acids.

Alloy 28 has corrosion rates less than 0.1 mm per year in high concentration sulfuric acids, up to a temperature of 50 degrees Celsius. This grade has also performed well in phosphoric acid heaters with under conditions of phosphate rocks contaminated with high concentration of chlorides and fluorides. 904L has also been used extensively in phosphoric acid industry.

Applications

Conventional and Bio Refineries: Several exchangers work as condensers and coolers. For overhead condensers, surface condensers, coolers and interstage coolers using water on tube side, often can face pitting corrosion, the extent of which depending on water quality, % of chlorides, and temperatures. Due to high pitting resistance equivalent number of super austenitic, this can be used in such conditions. Higher temperature limits of super austenite’s as compared to duplex grades also reduces the chance of tube failures, due to operational upsets, resulting in increase in surface temperature conditions. The fouling factor should also be considered, which increases surface temperature leading to pre-mature failure of duplex grades. Lean and rich amine coolers have similar conditions and can be potential application for super austenitic grade. There are already references of 6 Moly and Alloy 28 used for such applications in refineries. Other potential applications in refineries include sour water strippers and sulfur condensers. Additionally, high Moly % on super austenitic grades make it suitable for resisting naphthenic acid corrosion.

Sulfuric and Phosphoric Acid Industry: Some of super austenitic steels like Alloy 28, 904L, and Alloy 926, which can also be referred to as Nickel-Chromium-Molybdenum-Copper alloyed steels, have good resistance to these acids. Sites producing sulfuric and phosphoric acid, or industries using these acids for other refining and treatment purposes are applicable, such as Copper refining. Applicable exchangers include sulfuric acid coolers, phosphoric acid heaters (used in phosphoric acid production by wet process), and acid reheaters.

Flue gas condensers are also subjected to corrosion on tubes, due to condensing sulfur vapours, forming sulfuric acid in combination with moisture. Super austenitic steels are good for pipes carrying diluted sulfuric acid and phosphoric acid even if they are contaminated.

LNG / Cryogenics: Most of super austenitic steel grades have negative 175º C as the lower end of operating temperatures. Therefore, it has a dual advantage of being able to work in cryogenic atmosphere, and at the same time, have good resistance to pitting corrosion. Standard austenitic steels like 316L can also be used in cryogenic conditions, but they have much less resistance to chloride pitting as compared to super austenite’s.

Conclusion

Super austenitic steels have superior corrosion resistance properties, both in terms of pitting and stress corrosion, compared to standard austenitic steels. Additionally, it is equally or better placed compared to duplex steels. Although the application in high concentration and polluted acids would be limited based on temperature, it has been widely used in reducing and oxidizing acids at all concentrations. It is more stable on price and availability compared to high Nickel alloyed steels, and can be looked at as an option accordingly, depending on process conditions and the end application. It is also easy to weld and fabricate. These materials are available in various forms including sheets, plates, pipes, tubes, fittings, and more.

Reference

- Alloy selection in wet-process phosphoric acid, Nickel Institute, 2020