Today, experienced machinists, fabricators, machine shop owners, and OEMs use their trade skills and experience to shape and reshape the world we live in. In all cases, the question is not, can they machine complex metal parts and components, but rather, can they do it efficiently for their customers and profitably for their employers?

When operations like oil refineries, mines, dams, shipyards, and power plants experience a mechanical breakdown, it can cost them millions of dollars every day. Traditionally, these mission-critical assets would be dismantled and transported to the machine shop before being repaired and sent back. Using portable machine tools, however, can be the best way to reduce downtime and increase productivity by remachining and repairing those assets onsite.

By Dave Baker, CLIMAX

The Origins of Portable Machine Tools

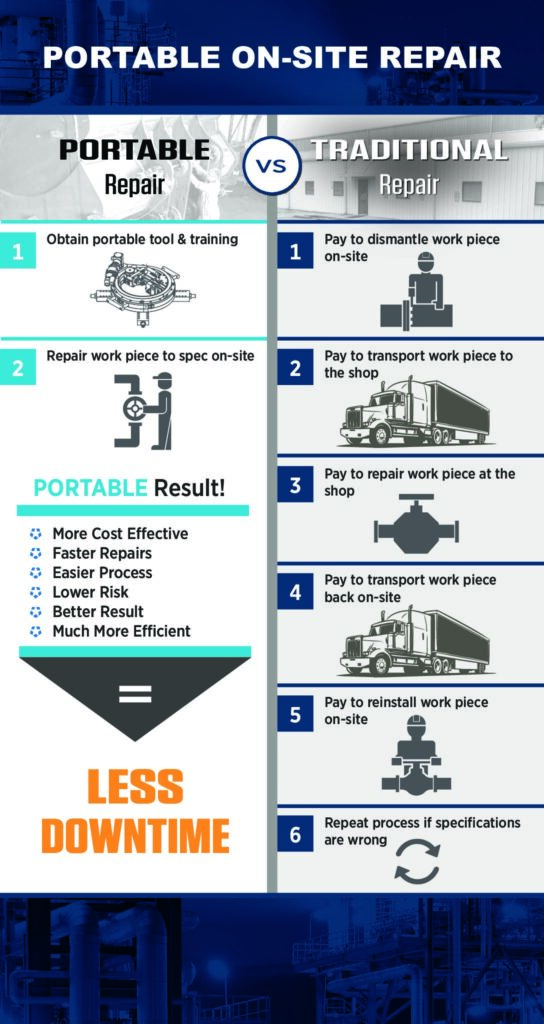

Paul Strait operated a machine shop, Coastal Machine Works, in Tillamook, Oregon in the early 1960s. Strait recognized that plants and operators could get more work done, faster, and more cost effectively, if they had machine tools available to do the work onsite. Traditionally, when planning maintenance or dealing with breakdowns, operators would have to stop production, dismantle the large work piece, and pay to transport the work piece to the repair shop. The repair shop would then complete the repairs, and transport the work piece back to the operator, where the work piece would need to be reinstalled. If for some reason the repair was out of spec, the operator would have to repeat the whole process again, resulting in significant downtime and expense.

In 1965, Strait invented a portable Key Mill to cut full depth keyways or mill small flats. By utilizing the portable Key Mill, operators and plants could now repair shafts and journals onsite, eliminating the costly downtime and transportation of equipment offsite. Repairing the work piece onsite was much faster, more cost effective, and mitigated several risks and safety concerns associated with the handling of moving the work piece.

The Key Mill saved so much downtime that it was rapidly adopted by maintenance personnel in sawmills and papermills all along the West Coast, and the portable machine tool solution was born. Soon thereafter, Strait founded Climax Portable Machine Tools which has since designed and engineered Portable Lathes, Flange Refacing Machines, Portable Milling Machines, Valve Repair Machines, Pipe Cutting and Beveling Machines, Drills and Line Boring, and Welding Machines used to perform a wide range of machining operations onsite, operations that traditionally could only happen offsite in a machine shop.

“The traditional stationary machining process takes multiple steps and is very time-consuming and expensive,” said Tom Cunningham, current President and CEO of Climax Portable Machine Tools. “While the workpiece is being repaired offsite, the system might be down, costing the operator thousands or even millions of dollars a day in lost production. The value proposition for onsite machine tools is very significant, which is why we continue to see growth in our industry every year”

How do Portable Machine Tools Compare to Stationary Machines?

Like stationary machines, portable machine tools are designed to utilize industrial power sources, precision cutting tools, and rigid positioning systems, such as rugged rails and ways, and precision ball screws. Portable machine tools, like stationary machines, will include firm clamping devices, heavy duty bearing systems, and a rugged platform foundation to maximize rigidity.

Machinists measure performance to the 1,000th of an inch because quality will never be perfect. All metal bends and everything deflects. The farther a tool is from the support, the more the system will deflect and impact machining performance. Well-designed Portable Machine Tools are engineered with support bearings located much closer to the cutting surface than many stationary machines. This is done to reduce deflection and reduce the distance between the cutting tool and the support – minimizing the amount of force it takes to hold the tool to the workpiece.

If the portable machine tool is designed right, it can last a very long time and allow users the flexibility to perform a much wider variety of machining applications. It can also utilize tooling that can cut hard-er materials, and achieve higher precision and surface finishes – all onsite.

For example, Portable Machine Tools can be an ideal solution for manufacturers of large parts or assemblies for wind towers. It is often safer and more productive to use a portable machine tool instead of trying to make the workpiece flow through a manufacturing line or cell. OEM’s can keep the workpiece stationary, like a wind tower section, and use the portable machine tool to complete the process.

A Portable Circular Mill, like the CLIMAX CM6200 pictured, can achieve flatness of .002” (.05mm) on a five-meter diameter wind tower flange. This is accomplished because the precision machined hub weldment ensures results in tight flatness tolerance. The multiple point support for the turning arm improves flatness. The preloaded bearing system reduces system compliance, and the self-compensating drive system is designed to minimize backlash.

Benefits and Applications

Companies today are being forced to solve some bigger problems now. Outages and turnarounds that used to last 60 to 90 days are now being done in less than a month, and in some cases weeks. Because of this new dynamic, there are seven distinct reasons why machining operations should consider adding portable machine tools to their ‘toolbox’:

1. Flexibility – Portable machine tools can be used for a wide range of machining applications without having to fully disassemble the workpiece to send it to the machine shop. This gives technicians the ability to move the operation to and around the workpiece, not the other way around.

2. Cost Effective – Significant resources need to be allocated for facilities big enough and capable of transporting and repairing large equipment like cranes, ships, valves, piping systems, or wind towers. A portable machine tool can be used for the work, and they can be much more economical to acquire or rent, utilize, and store.

3. High Return on Investment (ROI) –Because many projects are mission critical and portable machine tools can tackle a wide variety of projects and applications, companies can earn a return on the machine tool in some cases on the very first job.

4. Accuracy – Greater accuracy can be achieved in some cases with a portable machine tool because its design allows it to adapt to the machining application and puts the rigidity required to support the machining forces as close to the machining surface as possible.

5. Accessibility – Portable machine tools are often easier to access. They typically have shorter lead times and in emergent situations you can rent a portable machine tool. There is no other option that will allow you to quickly extend your machining capabilities like a portable machine tool can.

6. Efficiency – Portable machine tools are easy to set up and calibrate. Skilled technicians can be onsite with the right tool within a matter of minutes to repair something that would normally take several days.

7. Safety – Removing and transporting assets to a machine shop requires several people and multiple touch points along the way. Utilizing a portable machine tool reduces the resources and touch points required to make repairs, mitigating several safety concerns along the way.

When large parts, assemblies or critical components are down, minutes matter. The costs, safety risks, and down-time can be significant when navigating the manufacturing or repair of these large parts through stationary machining centers, and the downtime can be extensive, resulting in lost opportunity and lost revenue. Whether you are milling, boring, drilling, or turning, having the choice to use a machine shop or bringing the machining operation to the asset in need of repair can have a huge impact on an organization’s bottom line and a company’s ability to provide exceptional service to their clients.

The term ‘portable’ truly encompasses the overall value of a portable machine tool. Because these tools are compact and modularly designed, technicians now have access to machining equipment that can be easily transported and assembled at the workpiece, in the plant or shop, or in the field where users can begin repairs within an hour or less.

If you are an owner operator, operator of a machine shop, general contractor or industrial repair company, portable machine tools can be the best way to expand your services and capabilities and provide unmatched value to your customers, in a world that’s trying to solve big problems quickly!

About the Author

Dave Baker currently lives in Houston, TX, and graduated from Lehigh University in Bethlehem, PA. He has over 25 years of experience building and leading commercial teams and operations. Currently, he is Corporate Vice President of Sales and Marketing with CLIMAX Portable Machine Tools, and has been with CLIMAX since 2010.

For more information, please visit https://www.climaxportable.com/