Manufacturer representatives play a vital role in the relationship between manufacturers and end users. With a breadth of knowledge, these representatives can help end users make informed decisions about their applications.

Stainless Steel World Americas had the pleasure of speaking to Michael Dillon, Associate at Saxon Company, where he shares his input on cost considerations for heat exchangers, working as a manufacturer’s representative, as well as future thoughts about the industry.

By Charlie Evans & Shopia Ketheeswararajah

Dillon initially got his start going to college for premed. “I started my own business doing small engine repairs and got some smaller industry experience. From there, I took the same knowledge and applied it to bigger engines.” Following an internship, Dillon approached work from a different perspective. “I began working with cooling systems, which were a whole new thing altogether.”

Over the past five years, Dillon has worked as an Associate at Saxon Company, an authorized manufacturer’s representative. “I am both a sales manager and a project manager. Additionally, I also work in field service using heat exchangers and heat transfer equipment,” Dillon said.

Working Together

“Now I am in a customer-facing role, as I manage all the sales for Saxon Company. In my day-to-day, I cultivate relationships with the end users, the packagers, the OEM equipment people, and so on. From there, it is all about finding solutions to problems for customers, and most of the time, the customers themselves may not be the experts, but they know what they want, my job is to facilitate that,” said Dillon.

“I originally thought heat exchangers were easy, and then I started working with them,” said Dillon. “You learn there are many different size types, variations in materials, different pressures; there was a lot of learning on my side of things. The customer may not necessarily have all that knowledge, so it is important for me to keep their best interest in mind.” From there, Dillon receives feedback from the customer and determines the best solution to their needs. “There is always something we can do. I love fixing problems for people. I welcome a challenge and being able to provide customers with solutions is one of the most rewarding parts of my work.”

Cost Consideration for Heat Exchangers

More than half of Dillon’s business is comprised of engine applications. The customer reports the engine data indicating flow, heat rejection, and required temperature. He then informs the client of a suitable size that is needed to fit their specifications. This allows Dillon to establish how much material is required. He describes this as a balancing game. “If there is too much flow, the equipment risks erosion. On the other hand, when the flow is too little, it becomes laminar or alternatively, the client would need to add turbulators,” he said. “You start in the middle and say we need X amount of material to accomplish this. At this point, it is crucial to find out what the needs of the application are. It is important to determine what is going to drive this product, and if there are special requirements that must be met. This is where I start the conversation,” explained Dillon.

“Everything always goes back to the application,” said Dillon. For example, when a customer uses their own generators to supply power with the intention of avoiding additional charges during peak demand, it is called peak shaving. “In this scenario, a customer may find it cheaper to own a generator, burn the natural gas, and sell the power back to the grid. With that in mind, parasitic horsepower draw becomes a key characteristic that should be monitored closely,” he added. At this point, Dillon will work out some equations to determine how much power and money will be saved. “This can vary from project to project.” With peak shavings, Dillon will generally lower the horsepower drawn from the motors. “Any power I do not use with the heat exchanger, can be sold back. It is a win-win situation.”

Offshore Applications

Offshore projects have different sets of requirements that need to be met. “With onshore, I can sometimes save cost, with offshore projects, this becomes challenging, and the heat transfer equipment requires special coatings,” he stated. There are certain applications where the equipment does not require a special coating or material. “If you send something offshore that is not galvanized or coated, the heat exchanger will have a short service life. When coatings are implemented correctly, it maximizes the equipment’s service life and reduces the cost of repairs.”

Coatings used for offshore equipment are specialized. “We regularly use a phenolic coating that has a good salt spray test, or alternatively, an electrodeposition is utilized. This is also known as an e-coat. The process of employing an e-coat consists of applying a protective layer to a metal object using an electrical current. This gives the equipment a corrosions resistant finish,” he shared. “Getting applications serviced for offshore equipment is a much more complicated endeavor than onshore.”

Material Selection for Heat Exchangers

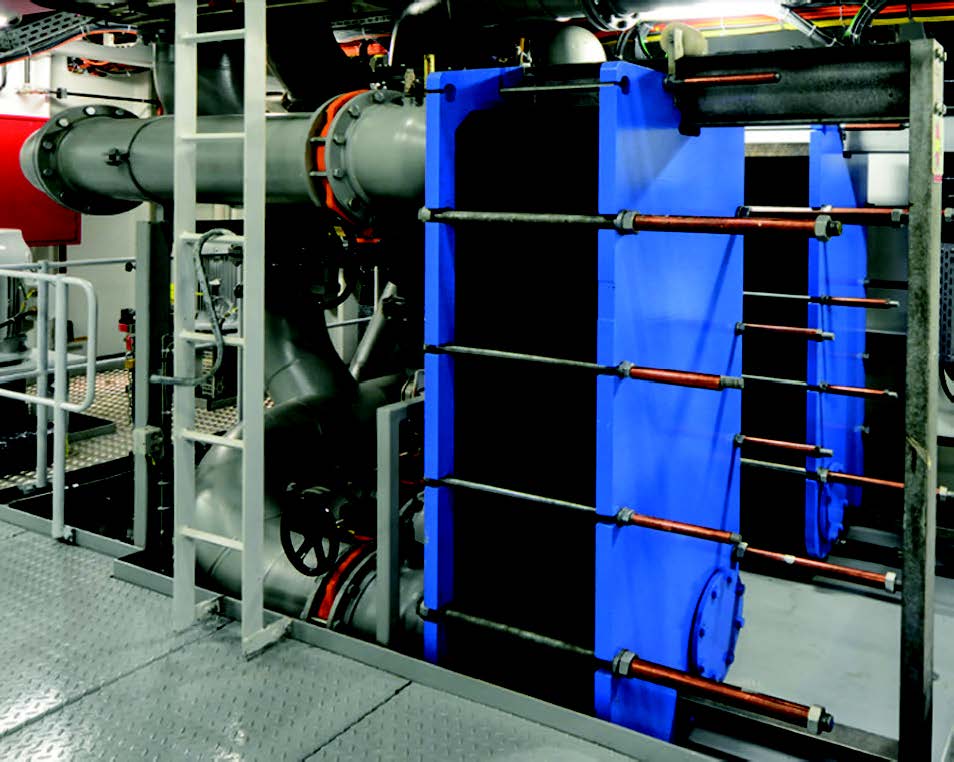

Heat exchangers have a wide variety of materials. “Material selection can be a tricky question. If you are looking at a pressure vessel with API 660 or 661, it has a different material selection and design than a non-coded exchanger. A lot of the time it depends on the size of the equipment, ”said Dillon. A lot of heat exchangers use copper or aluminum for the heat transfer material and carbon for the structure. Specialized exchangers for offshore or marine projects can use copper nickel, brass, galvanized steel, or titanium. Other industries, such as food or pharmaceutical grade typically utilize stainless steel with special requirements. “It really comes down to the application in order to determine the material that needs to be used, based on certain specifications,” he added.

Most heat exchangers have a steel support structure. “High pressure heat transfer equipment has to be strong enough to hold the desired pressure, which drives material selection and thicknesses,” said Dillon. “ We use stainless steel for corrosion resistance on certain applications from natural gas projects, guarding on offshore projects, and some seawater applications. Certain projects will require titanium or inconels for more demanding applications.

Common Challenges

Since the COVID-19 pandemic, the supply chain has been a point of frustration. “I started this position two years before COVID, so I have seen the supply chain working from all sides,” said Dillon. “The supply chain will appear to have recovered from COVID, and then it will be clear that it has not.” When the delivery of components is delayed, unexpected downtimes are hard to avoid. “It depends on the week. Sometimes the assets themselves are delayed, sometimes it’s the people who are delayed.”

“For example, welding can sometimes bring forth a challenge. There was a point in time where it was difficult to employ welders,” explained Dillon. “We had to go to another company to get our parts welded and send it back to the customer.” Ultimately, the customer wants a successful job done. “They do not want to hear that we do not have the time or capability to do something, so that enables us to get creative and be able to pivot quickly to different solutions.” This leads to maneuvering around and finding new people to work with on an as-needed basis.

Future of the Industry

“Emissions are a big part of the future of the industry,” commented Dillon. “All manufacturers and service shops are compliant with Environmental Protection Agency (EPA) on all manufacturing processes. Emissions monitoring is changing our industry, but it is also helping it. We have done a lot of work with oil and gas, and we are now seeing a lot of that become electrified.” However, this also leads to a power demand increase. “Anything that makes power, makes heat, and that is where I come in. Even a lot of our carbon capture systems have heat exchangers of some type. Overall, there will be a shift in our day-to-day tasks, especially when it comes to the oil field.”

When asked about words of wisdom for newcomers in the industry, Dillon said, “I have three facets of advice: do not be afraid to fail, continue your education, and keep going. We have had projects that we have had to rebuild; projects that may not have been perfect, and that is okay. The mindset that you cannot fail held me back at first, especially when it came to cold calling. But eventually I realized that making mistakes is a vital learning process,” he added. Dillon expressed the importance of attending industry events, networking, and ongoing learning. “Staying up to date with conferences and tradeshows can be immensely rewarding for those who are just entering the industry. Make sure you meet new people, and no matter what, do not give up.”