After many years of working on a new super-austenitic alloy, the time was right for its first commercial application. Confident collaboration between

the material manufacturer, the fabricator, and the end user ensured a successful outcome.

By Dinesh Bakshi, Brask Inc., and Jennifer Svensson, Alleima

A Hot Market

The acceleration of economies around the world after more than two years of the pandemic is boosting the demand for refined products. It is also increasing the need for components and services to support their production.

For example, the global shell and tube heat exchanger market, estimated at $5.68 billion in 2019, is expected to grow by more than 6% by 20271. This is due to several factors. These include a greater focus on thermal efficiency in industries including oil & gas, power generation, chemical and petrochemical, food and beverage, and HVAC and refrigeration.

Many processes in petrochemical facilities involve high pressure and temperature. Optimized heat transfer and the enhancement of energy savings are critical.

The U.S. dominated North American heat exchanger demand in 20212. This was due to high electricity demand, industrialization, and investments in renewable power generation. In this period of demand growth, technological advances to improve energy efficiency, total life cycle cost, and the durability of heat exchangers are essential.

As end customers seek ever-greater cost efficiencies from their suppliers, collaboration between trusted manufacturers and fabricators can generate significant financial and performance benefits.

The Challenge

Alleima, formerly Sandvik Materials Technology, is a world-leading developer and manufacturer of advanced stainless steels and special alloys. The company recently secured an order to supply tubes for two heat exchangers used in a crude unit fractionator at a major refining company on the U.S. Gulf Coast.

The refinery had a history of significant corrosion challenges in its heat exchangers over several years. Hydrochloric acid condensation was causing localized corrosion, pitting, and fouling. Improper water wash for the system was generating salt formations.

Previously, the bundles had been made from hyper duplex stainless steel tubes. However, the refinery’s challenging process conditions, and the need for a material that could significantly extend the life of the tubes, called for an even higher corrosion-resistant alloy. It was time for a new solution.

A Progressive Partnership

The development of a new material takes several years of research and development. It begins with a market need, and a company’s commitment to develop innovative solutions that fill the gap between stainless steels and costly nickel alloys.

Once the metallurgy is ready for deployment it is important to find the right opportunity. For example, the long-standing relationship between Alleima and the end client, including detailed discussions on the development of the Sanicro® 35 and the testing of samples, gave the company the confidence to suggest it as a solution for replacing the heat exchanger tubes.

The end client reviewed several metallurgy options and carried out cost benefit analyses on each one based on the expected lifecycle.

After an extensive evaluation of the corrosion and mechanical properties compared to other high-cost nickel alloys under consideration, the refinery selected this alloy for its high performance and cost alternative offering.

Tube Material Supplier and Fabricator Collaboration

Simultaneously, the company was in ongoing communication with fabricator Brask Inc over the development of the alloy. Brask specializes in the design, manufacture, and repair of shell and tube heat exchangers and pressure vessels.

Continuous feedback on the advancement of Sanicro® 35 increased awareness and understanding of the grade’s progression to the point of its commercialization. It also supported confidence in proving to the end client that fabrication with the material would be straightforward. Heat exchanger bundles for the same end client had been fabricated from hyper-duplex SAF® 2707 HD in the past. Using Sanicro® 35 this time, the fabrication was equally seamless and without issue.

The tube material was manufactured in the Czech Republic. However, the lead time was shortened at the request of the end user. To meet the new deadline, the tubes were airfreighted to the U.S., so that fabrication could begin.

In-depth collaboration between the manufacturer and the fabricator early on, including several meetings between the welding experts for alignment on welding procedures, generated confidence on both sides. The early share of information by the stainless producer allowed the fabricator to complete its due diligence and design analysis.

Tube samples were supplied in advance so welders could perfect welding details including machine parameters, and gain comfort with weldability of the tube, tubesheet and filler metals selected. Important technical information such as the code case details was also provided, which supports input on filler metal selection, ensuring fabrication went to plan.

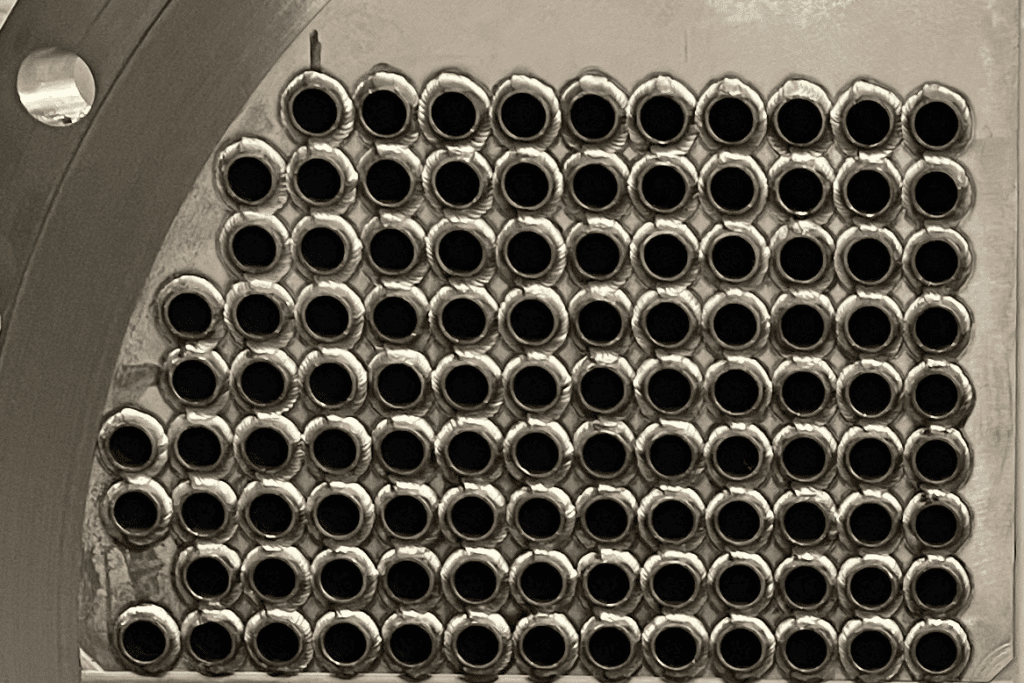

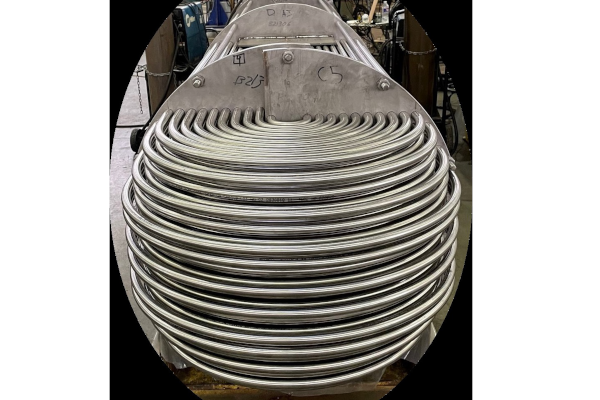

Using leveraged past experience and test knowledge, welding of the tube to tubesheet joint with no issues was completed. In this case, the tubesheet metallurgy specified was Super Duplex, UNS S32750. The workability of Sanicro 35® was similar to duplex and hyper-duplex materials used in the past. Each of the bundles consisted of 214 U-Tubes and fabrication took three weeks.

The bundles were installed in December 2021 and as of this writing are performing without issue. The end client has also recently expressed interest in procuring two more heat exchanger bundles to be made with Sanicro® 35 tubes.

To achieve success in completing the first project with a new alloy, the strong partnership between the tube manufacturer and the fabricator was critical. Both teams collaborated and drew from expertise in developing and working with a range of stainless steel and nickel alloys to deliver the solution to the end user.

Advancing Materials Technology

This was the first order for the Sanicro® 35 (UNS N08935) super-austenitic grade. It is a high-performance alternative to existing duplex and austenitic stainless steel grades and more expensive nickel alloys. It offers exceptionally high performance, strength, and corrosion resistance at a wide range of temperatures.

It is a highly alloyed and chemically balanced PRE 52 super-austenitic grade that offers extreme pitting resistance and outperforms conventional 6Mo alloys. The material’s ability to provide a high level of corrosion resistance and strength gives it an excellent price performance ratio compared to alloys with higher nickel content. Its high structural stability provides reassurance that it will maintain its microstructure after welding, so the weld area is not a weak point when in service. This helps minimize risks and extends the lifecycle when battling corrosion.

Combining the mechanical properties of duplex grades with localized crevice corrosion resistance comparable to alloy C276, Sanicro® 35 has a critical pitting temperature (CPT) of 110°C (230°F) per ASTM G150 in a modified and more severe 3M Magnesium Chloride (MgCl2) solution. Its high yield strength enables reduced wall thicknesses, creating significant weight savings. It also has a very high resistance to stress corrosion cracking.

For fabricators, it requires no pre-heating or post-weld heat treatment. Its high structural stability means it is not prone to intermetallic phases during welding. The excellent formability of the grade permits cold bending to tight bending radii. Cutting, turning, drilling, and milling are also easier than with a tough nickel alloy tube.

Designed for extremely corrosive environments and seawater applications, it is ideal for heat exchangers and hydraulic and instrumentation tubing. It offers a cost-efficient choice for minimizing risk and extending production lifecycles when battling corrosion in demanding environments.

Advancing Together Through Trust

Producing heat exchanger tubes for a crude unit fractionator using a relatively new material proved the value in trust between the material manufacturer, the fabricator, and the end customer. Sanicro® 35 represents an exciting material option available for the end user to evaluate for their particular process equipment challenges.

References

1) https://www.grandviewresearch.com/industry-analysis/ shell-tube-heat-exchangers-market

2) https://www.grandviewresearch.com/industry-analysis/heat-exchangers-market#:~:text=Key%20factors%20that%20 are%20driving,focus%20on%20improving%20efficiency%20 standards.