The market for stainless steel in the power industry will grow at a Compound Annual Growth Rate (CAGR) of 2% over the next 30 years. It is predicted that this already massive market will increase further as the innovation needed to reach the net zero CO2 initiative occurs. This in turn will require coal and nuclear plants to allocate more spending to stainless steel technologies.

By Robert McIlvaine, President & Founder, The McIlvane Company

Why stainless steel?

The International Energy Agency (IEA) intends to reach global net zero CO2 emissions by 2050. To achieve this, the energy industry needs to make some serious changes, namely to the kinds of technologies used within power plants.

Already, stainless steel is a vital material within the power industry, but the purchases required for a wind or solar plant are smaller than those required for a coal power plant. Since the projected capacity for wind and so-lar is large, and the projected capacity additions for coal and nuclear plants are modest, it seems logical that the market for power plant stainless steel would be unattractive compared to other market opportunities — but this is not the case.

Instead, this market will become in-credibly attractive. This is in part be-cause of the already extensive size of the stainless steel market — though the need for process innovation and improved technologies will also contribute to higher stainless steel expenditures within power plants. This is especially true for coal-based power plants.

Stainless steel innovation

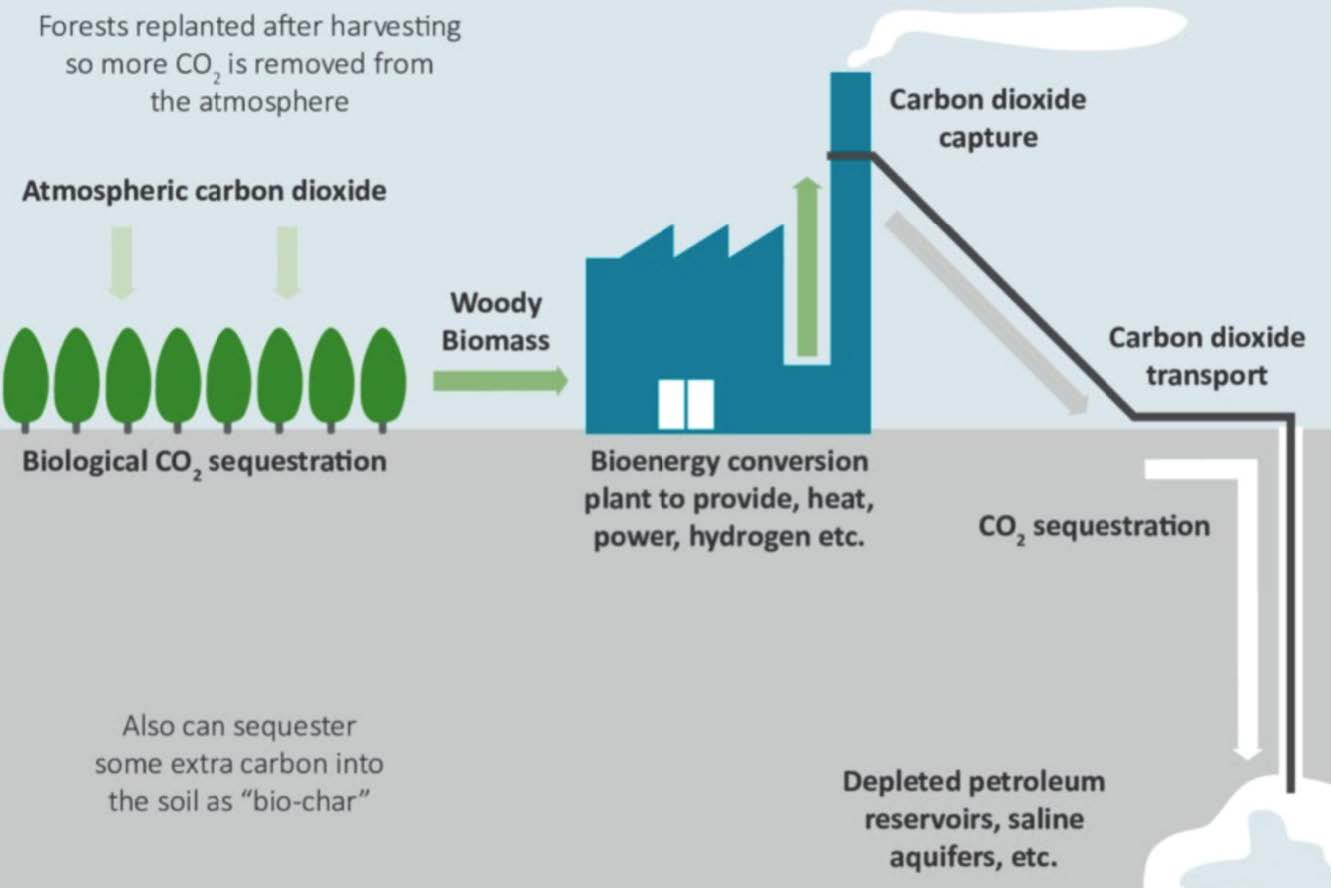

Bioenergy with carbon capture and storage (BECCS) is a promising future for the power industry, specifically for coal processing plants. This carbon removal technique extracts bioenergy and biomass to remove carbon dioxide and greenhouse gases from the atmosphere. This technique is not only workable and valid, but also cost-effective.

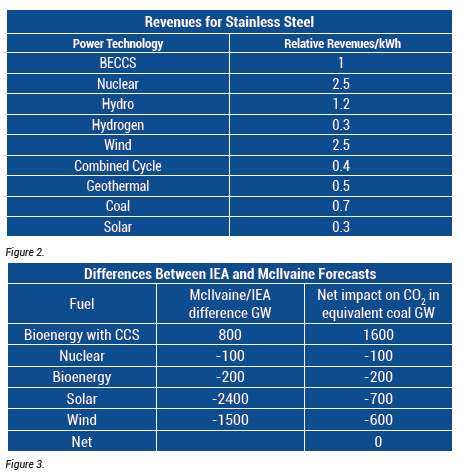

The technologies necessary to provide high-capacity factor electricity for this geo-engineering technique however, require lots of stainless steel. This is true of a number of diverse power technologies, though BECCS and hydrogen require more stainless steel than other power generation options. This is illustrated on a comparison per kW, see Figure 2.

BECCS has twice the CO2 reduction impact of nuclear due to removal of CO2 from the air prior to burning and sequestration. Solar and wind have a smaller impact on a net CO2 reduction basis per GW due to their lower capacity factors.

Stainless steel in hydrogen power technology

In a green hydrogen plant, stainless is used in the purification and transport of water to the electrolyzer; a system used to separate hydrogen and oxygen atoms in H2O.

As Blue hydrogen, which is derived from methane in natural gas, requires ample stainless steel because energy is created from processes which generate CO2, carbon capture and storage (CCS) is necessary. Generally acceptable materials for creating CCS technology include: austenitic stainless steels, aluminum alloys, copper, and copper alloys.

Nickel and most nickel alloys should not be used since they are subject to severe hydrogen embrittlement. Gray, ductile, and malleable cast irons should also not be used for hydrogen service. From the metallurgy side, manufacturers need to consider the adverse effects that hydrogen at elevated temperatures and pressures can have on carbon and low alloy steels, such as hydrogen embrittlement, high temperature hydrogen attack and hydrogen blistering.

Hydrogen is colorless, odorless and highly explosive, has low viscosity, low molecular weight and is an asphyxiant. These characteristics make zero leakage a necessity. This is why stainless steel expenditures are predicted to increase within the hydrogen power processing industry.

Stainless steel in BECCS power technology

Stainless steel is one of the most predominant construction materials in BECCS bioengineering. The use of stainless steel in BECCS processes starts at the wood pellet plant. Scrubbers and wet electrostatic precipitators are often used to reduce stack emissions from the pelletizing operation, before the wood pellets are shipped to a power plant where they substitute for coal as the fuel.

If it is a coal-fired plant, such as Drax in North Yorkshire, England, stainless steel is required for conversion of materials into biomass. This includes usage in the boiler feed, water intake, and cooling processes.

Within BECCS power technology, stainless steel is also used to control air and water pollution, including in the flue-gas desulfurization (FGD) systems. For post-combustion CO2 capture operations at coal-fired power plants, capital expenditures for process units such as the absorber and stripper as well as piping, make up a significant percentage (approximately 50%) of the cost. Although a variety of materials have been used for these process units (for example, concrete is sometimes employed for building absorber columns), stainless steel is still the predominant construction material.

Once captured, the CO2 must be transported to a permanent storage site. Currently, the most economical method for transporting large volumes of CO2 is via pipeline. To make this possible, the CO2 is converted into a high-pressure, super-critical fluid called dense phase. In this phase the CO2 behaves more like a liquid than a gas, allowing it to be pumped.

Another method of CO2 sequestration involves injection into geological reservoirs. The most economically viable of these is enhanced oil recovery (EOR), where CO2 is injected into active oil fields to increase production. The gas can also be injected into unusable saline aquifers and depleted oil and natural gas reservoirs. Again, stainless steel is a necessary material for these processes.

The advantages of BECCS

Regardless of the method, BECCS has a number of advantages. The most obvious is that it is carbon negative. If all coal-fired plants in the world were converted to BECCS, global CO2 levels could be reduced; this option eliminates the tipping point worry.

Another advantage is the cost. The only other carbon negative technology is Direct Air Capture. The cost of this option, however, is quite high. BECCS, on the other hand, can utilize existing coal plant steam generators and pollution control systems. The major capital cost is in the actual carbon capture and sequestration process.

The tipping point worry phenomenon occurs when global temperatures exceed a critical threshold, causing advanced and irreversible environmental damage.

The biggest advantage of BECCS is the potential of utilizing a staged approach, or the easy, slow implementation of BECCS processes in existing coal plants. The steps to implement BECCS are as follows:

1. Co-firing biomass at existing coal plants.

2. Complete conversion to biomass.

3. Partial carbon capture and sequestration or usage.

4. Full carbon capture and sequestration or use

The Drax power plant in the UK is already moving from stage to stage. Though they are now at stage two, engineering and construction is underway for stage three. This flexible approach is very desirable due to the uncertainties about CO2 impacts. The program can be accelerated if some of the more dire predictions materialize. The net zero program will result in modest growth in the market for power plant stainless steel over the next 30 years.

About the author

Robert McIlvaine is the CEO of the McIlvaine Company, which publishes Industrial Valves: World Markets. He was a pollution control company executive prior to 1974 when he founded the present company. McIlvaine oversees a staff of 30 people in the U.S. and China. http://www.mcilvainecompany.com