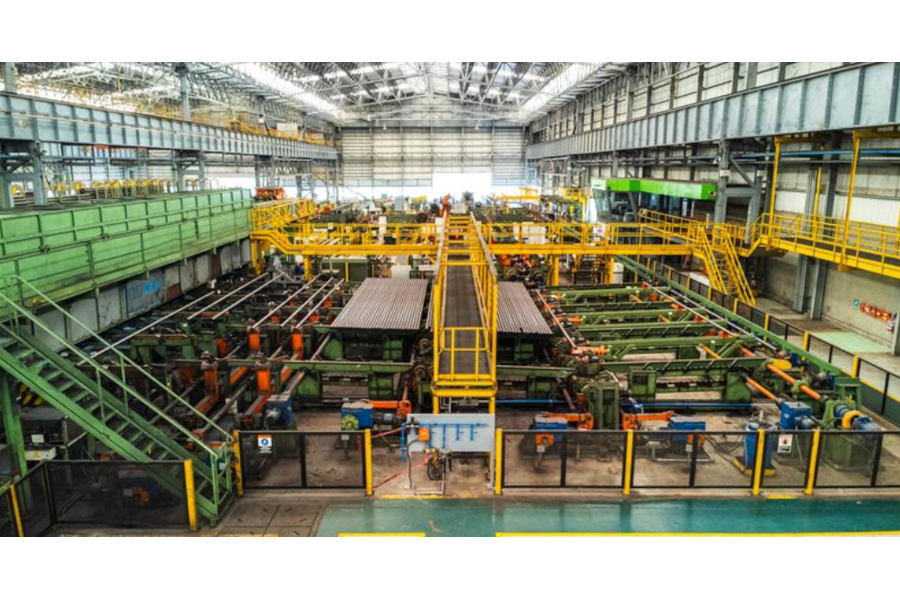

The startup of a new automated inspection line marks a milestone for TuboCaribe, Tenaris’s production center in Cartagena, Colombia. This reinforces the competitiveness and sustainability of the operations through improvements in safety, quality, and efficiency.

Hydrostatic testing of tubing and inspection activities are now supported by automated systems that optimize workflow and improve conditions for shop floor employees. The inspection area has been expanded from about 21,500 to 32,300 square feet, allowing greater mobility, organization, and coordination.

Operations now take place in a controlled setting in which technology guides every stage of the process. Pipes are moved automatically, ultrasonic sensors detect potential defects, and direct physical contact with the pipes has been eliminated. This shift allows teams to focus fully on quality assurance and process control rather than performing manual tasks to move and position pipes.

Courtesy of Tenaris.