Stainless steel is often viewed as virtually indestructible when it comes to corrosion. After all, “stainless” is right there in the name. But even this incredibly versatile material is not immune. Under the right—or rather, wrong—conditions, stainless steel can fall victim to insidious attacks like pitting, crevice corrosion, and stress corrosion cracking. Protecting these vital assets is not just about prolonging their life; it is about maintaining their integrity and performance, whether they are in a chemical plant, a medical facility, or a marine environment. Vapor Phase Corrosion Inhibition (VpCI®) technology offers an effective and refined solution.

VpCI® technology has been tailored to meet the exacting demands of the stainless steel industry. It is a proactive, highly effective, and increasingly sustainable way to guard stainless steel components throughout their entire journey — from the moment they are made, through storage and shipping, and well into their operational life.

By Ana Juraga Oluic, Content Writer at Cortec Corporation

VpCI® Technology: A Molecular Shield for Stainless Steel

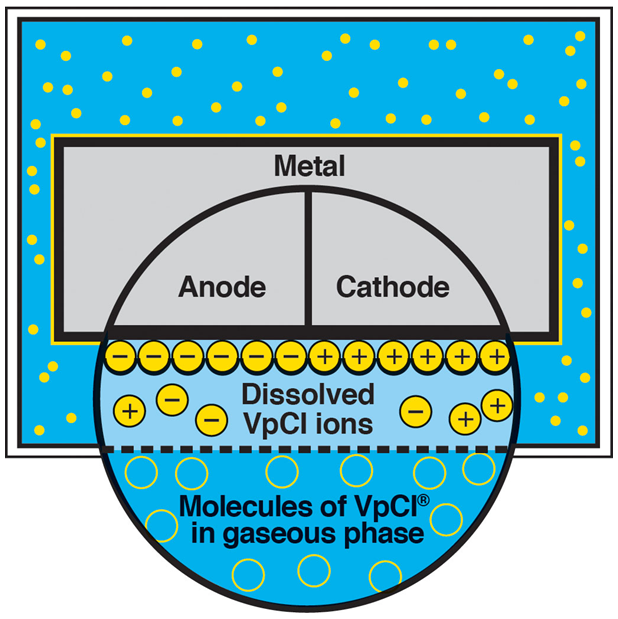

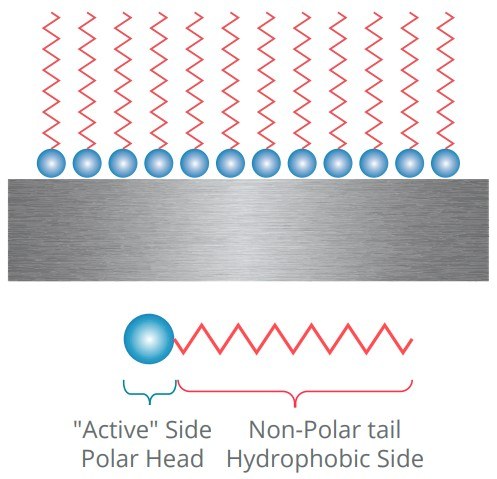

VpCI®’s value lies in its unique delivery method. Unlike traditional liquid coatings that need to be carefully applied to every surface, VpCI molecules are volatile — tiny, invisible guardians that evaporate and float through the air. They then permeate and protect even the most enclosed or hard-to-reach stainless steel surfaces, settling down to form a protective layer. This invisible shield specifically benefits those working with stainless steel.

Reaching the Unreachable: Stainless steel parts often have incredibly intricate designs, hidden cavities, or super-tight crevices. These are exactly the spots where traditional inhibitors struggle to reach. VpCI® molecules, by diffusing through the air, ensure complete protection for these challenging geometries, effectively fending off dreaded crevice corrosion.

Obstructing Localized Attacks: Pitting and crevice corrosion are big headaches for stainless steel. They exploit tiny imperfections or environmental differences. VpCI® molecules form a microscopic protective layer right on the stainless steel surface, including those vulnerable, localized spots. This blocks aggressive ions (like chlorides) and halts these destructive corrosion processes even before they begin.

Protection at Every Stage: From the moment stainless steel parts roll off the line, through temporary storage, packaging, and even long global shipments, they are constantly exposed to varying corrosive elements. VpCI® packaging films, papers, and emitters offer continuous, multi-metal protection, ensuring stainless steel arrives in pristine condition, with no unexpected rust spots or discoloration.

Stainless Steel Friendly: It is crucial to avoid anything that could interfere with stainless steel’s inherent properties or cause sensitization. VpCI® formulas are designed to be non-staining and compatible with all sorts of stainless steel grades, meaning no unwanted reactions or harm to the material’s crucial passive layer. Plus, they are typically free of nasty chemicals like nitrites, phosphates, and heavy metals.

Layup and Operational Preservation: For stainless steel equipment in industries like oil & gas or power generation, there are often periods of inactivity. VpCI® provides layup protection for the internal surfaces of pipes, tanks, and vessels, keeping them safe from corrosion during down time and simplifying the recommissioning process.

Tackling Stainless Steel’s Specific Weak Spots with VpCI®

Even with its strong reputation as corrosion resistant, stainless steel does exhibit particular vulnerabilities:

Pitting Corrosion: This highly concentrated attack can quickly punch holes in the passive film. VpCI® creates a barrier that interferes with the electrochemical reactions needed for pitting to begin.

Crevice Corrosion: This notorious issue for stainless steels occurs in those oxygen-starved confined spaces. VpCI® vapors penetrate these tight areas, laying down a protective layer that liquid inhibitors cannot breech.

Stress Corrosion Cracking (SCC): While SCC is complex, VpCI® can help by generally making the environment less corrosive, which in turn reduces the chances of cracks forming and spreading when the material is under stress.

Ultimately, VpCI® solutions provide long-term protection, even in harsh industrial and marine environments, by continuously renewing that vital protective film on the stainless steel surface.

The Green Revolution in Stainless Steel Protection: Biobased VpCI®

The stainless steel industry, like many others, is increasingly focused on sustainability. They are seeking effective solutions that also minimize their environmental footprint. Some examples of these eco-conscious VpCI® innovations include:

EcoClean® Biodegradable Scale and Rust Remover: This product not only strips away rust and scale from stainless steel but also has VpCI® technology built in to protect the newly cleaned metal from instant re-corrosion.

EcoLine® Biobased Rust Preventative: A high-performing, biobased alternative to the older, petroleum- based rust preventatives, it protects stainless steel components during storage and shipping.

Eco-Corr Film®: This advanced film, made with renewable content, delivers excellent contact, barrier, and VpCI® protection for stainless steel, making it a truly sustainable packaging choice.

Conclusion

Manufacturers and users working with stainless steel can assess the suitability of biobased VpCI® solutions for their specific needs and as an environmentally friendly agent with reduced harsh chemicals, all while providing stainless steel with the strong corrosion protection it needs to last a long time.

Ana Juraga has been a content writer at Cortec Corporation for 15 years. Besides dealing with media relations she collaborates with Cortec’s engineers and chemists in creating informative technical content. She is passionate about educating the engineering community on green corrosion-inhibiting technologies and numerous advances in this field.

Ana Juraga has been a content writer at Cortec Corporation for 15 years. Besides dealing with media relations she collaborates with Cortec’s engineers and chemists in creating informative technical content. She is passionate about educating the engineering community on green corrosion-inhibiting technologies and numerous advances in this field.