Newer technologies and innovation are seemingly instantaneous. Change is everywhere and happening yesterday. A return to basics often sprouts fresh ideas and previously unseen initiatives that weather shifting global economic conditions and geopolitical uncertainties. This article will go back to basics and examine the differences between stainless steel piping and stainless steel tubing.

By Kristen Charles, Stainless Steel World Americas

Introduction

Proper material selection is essential before any project begins. While both stainless steel pipes and tubes are critical to many projects, their purposes are quite effective but different. Stainless steel pipe and tube might look similar but they are not interchangeable and often have clearly defined functions.

Size

Pipe size is typically identified and ordered by Nominal Pipe Size (NPS) and sized according to its interior capacity, or inside diameter (ID), and not the outside diameter (OD). Engineers employ this standard when designing projects to measure the volume the pipe can transport. Steel pipe is measured according to its wall thickness (W) and is enumerated as a “Schedule”. The higher the Schedule, the thicker the pipe wall will be. Likewise, the Schedule’s thickness increases as the size of the pipe increases. For example, a one-inch NPS Schedule 40 pipe wall is thinner than a three-inch NPS Schedule 40 pipe wall. Different-sized pipes can have the same schedule number but can have different wall thickness. A pipe’s dimensions help determine its liquid capacity.

Most stainless steel pipes are available in values such as Sch. STD., Sch. XS, Sch. XXS or Sch. 40.

The size of steel tube can be ordered using ID and W, but it is typically calculated using outside (OD) diameter and wall thickness. A tube’s strength is determined by its wall thickness, which is demarcated by a gauge number. The smaller the gauge number, the larger the OD. Steel tube is frequently employed for smaller diameters that require stringent tolerances.

Configuration

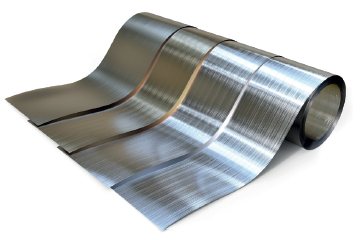

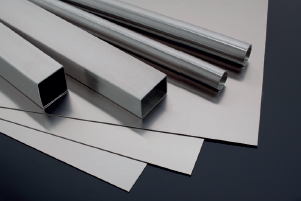

A stainless pipe’s construction is round; thus, a pipe’s cross section is round with a hollow center. A piping system’s construction facilitates the transfer of liquids, gases, powder, pellets, and steam. This can be determined by calculating the OD outer diameter minus 2 times wall thickness (or schedule).

Steel tube configuration can be round, like steel pipe, as well as rectangular, square, or oval. A tube’s hollow section is estimated by calculating the OD with wall thickness. Tube dimensions are conveyed in inches or millimeters and indicate a hollow section’s true dimensional value.

While pipes and tubes can be produced in numerous ways, including cut, bent or fabricated, pipes are applied in a wider range of applications and steel tubes are utilized for smaller diameters.

Applications

Piping systems are used primarily as a means of transporting various agents like fluids, gases, and steam, so capacity is critical. A pipe’s circular configuration allows for a higher level of proficiency when facilitating pressure from the circulating fluid flowing through the piping system. Because pipes function primarily as conduits for gasses and liquids, it is critical to understand a pipe’s capacity and the amount of liquid and gas the pipe can accommodate.

Steel tube is a dependable partner that is frequently used in applications that require an accurate outside diameter that demonstrates its ability to provide enduring stability. Its strength and durability are well documented and well suited for extensive industrial and commercial purposes.

The use of steel tubes is more prominent in structural environments like scaffolding or staging, as well as the construction of man-made structures like bridges and dwellings.

Strength, Maintenance and Versatility

While both steel pipe and tubing can be galvanized, pipe can only be hot rolled, while steel tubes can be hot rolled and cold rolled. Tubes exceed pipes in projects and purposes that demand fortitude and stability.

Steel tube provides telescoping abilities for expansion inside tubes and materials that require sleeving. Telescoping tubes are ideal for applications where different pieces of material are sleeved or expanded inside one another. Specialized thread-cutting tooling is not required during tube installation, and because tube wall sections tend to be thinner, tube provides expansive malleability.

Rigidity

Steel pipe requires special equipment to be shaped. It cannot be manipulated as easily as tubing, nor is it quick to install. Using elbows to facilitate usage increases the likelihood of leak paths because of all the additional fittings. Furthermore, taper-threaded pipe ends require thread sealant prior to assembly.

Steel tube can be shaped, although it does require additional effort; however, like steel pipe, steel tube is meant to be rigid because of its use in structural applications and its provision of load-bearing capabilities. Furthermore, tubing systems are easier to prepare for scheduled maintenance. Tubing does not weigh as much as pipe and wall thickness can be maintained because no accommodations need to be made for threading.

Tolerances

Steel pipes and tubes do have tolerance strictures. Because pipe comprises the transfer of various materials, pressure and tolerance parameters must be clearly defined. Steel tube production can involve either seamless or welded constructions; however, due to its place in structural applications, tube tolerances are more stringent than pipe. Testing, quality checks, and inspections are integral to the manufacturing process of tubing as a finished product.

Connections

Both steel pipe and tube can often require many connections. Connecting pipe is a copious and laborious process where each step must be performed carefully. Threading and welding using specialized tubes are required to ensure pieces fit properly. However, once the process is complete, pipe connections are typically strong and safe.

Tubes often provide simpler connectivity and typically require uncomplicated flaring and coupling. Fittings are used in more sensitive applications, but they are easily obtained. In addition, steel tubes are able to connect to themselves and other pieces if necessary.

The Threat of Leaks

Steel pipes that have threaded connections or welds have a higher chance of leaks at the connection points.

Steel tubes on the other hand are manufactured in a fashion that reduces the possibility of leaks and holes. Tubes are often manufactured with seamless construction, reducing the number of weak points.

Conclusion

The differences between stainless steel pipe and tube are numerous and varied, but both share common properties and benefits. Stainless steel is corrosion and rust resistant with the ability to endure harsh environments. Its corrosion resistance means it requires less maintenance. It has a reputation for high-tensile strength and has the ability to weather high temperatures and pressures.

Stainless steel pipes and tubes are versatile materials that offer the flexibility, as well as grade and size options that can be used across myriad applications, including chemical managing, construction, HVAC, and plumbing, and its recyclability coincides with climate change initiatives. Both stainless steel pipes and tubes have very different functions, but their commonality lies in their ability to reliably meet the needs of multi-faceted projects across numerous industries.

References:

- https://www.solitaire-overseas.com/blog/differencebetween-stainless-steel-pipe-and-tube-with-anexample/#:~:text=Stainless%20steel%20pipes%20and%20tubes%20are%20widely%20utilized%20across%20various,them%20ideal%20for%20diverse%20applications.

- https://www.union-steels.com/newsdetail/stainless-steel-pipe-advantages-and-disadvantages.html#:~:text=%2D%20Heavy%20Weight%3A%20Stainless%20steel%20pipe,may%20leak%20at%20the%20joint.

- https://www.iqsdirectory.com/articles/stainlesssteeltubing.html#:~:text=Benefits%20of%20Stainless%20Steel%20Tubing,-Stainless%20steel%20tubing&text=Its%20key%20benefits%20include%20exceptional,effectively%20for%20low%2Dpressure%20systems.

- https://songshunsteel.com/the-complete-guide-tostainless-steel-tube/#:~:text=Stainless%20steel%20tube%20is%20a,liquids%2C%20gases%2C%20and%20solids