Stainless Steel World Americas had the opportunity to speak with Vice Presidents Sam and Chait Desai, and President Mukesh Desai, about RM Creations’ history, the company’s domestic and export businesses, and how working with a family-run business can be beneficial for customers.

By Brittani Schroeder

A family operation

After many years of working in the steel industry with his family, Mukesh Desai and his wife Rashmi Desai decided to move to the United States to start their own company. In 1986, after establishing the business, the couple decided to incorporate their company, calling it RM Creations, Inc. They started in New York City and stayed there for over 20 years before moving to New Jersey. Being in New Jersey has allowed them to be closer to family and have a better working space. “Our headquarters is in New Jersey, U.S.A., but we buy and sell to over 28 countries including India, Taiwan, Vietnam, Brazil, Canada, and the United States,” says Sam. “We have warehouses in Chicago, Houston, Baltimore, and Los Angeles. We want to be able to reach as many customers as we can in a short amount of time.”

RM Creations has always been run by the Desai family, and the plan is to keep it that way. “We are a privately-owned company with 22 employees. Although this may seem small, the ability to work with a close-knit group of individuals has been very advantageous to us and our customers,” Sam explains. As a privately-owned company, the employees and senior management can make decisions quickly for their customers. He continues, “Being able to make decisions quickly means that we can stay up-to-date with industry trends to meet the needs of the constantly changing market. In this day and age, where trade duties and tariffs are always changing, and political and financial situations regularly fluctuate, we need to be fluid and move with the market.”

As a supplier of stainless steels and other metal products, RM Creations focuses their operations on two separate markets: domestic and international. Brothers Sam and Chait Desai split up the duties within the company; Sam focuses on the domestic operations and sales, and Chait focuses on the company’s scrap metal export business operations. Being involved in the domestic and international markets has allowed the company to get up to the minute market information which impacts their decisions daily. Mukesh, Sam, and Chait discuss their market intel daily in order to do proper buying and selling.

The company and their employees live by three values: honesty, integrity, and great customer service. Providing customers with quality and on-time service is, and always has been, the goal for RM Creations. “Providing the best service to our customers means giving them better pricing, on time deliveries, better quality, and continuously improving customer support. Our hope is to become the number one choice for our customers and our suppliers,” states Sam. For the company’s suppliers, this means paying invoices on time, adjusting to their schedules, and solving any issues that arise in a timely manner.

Research and development

When RM Creations is in the process of researching new products to offer, the first source they go to is the people they work closely with. “We personally visit our customers and suppliers to figure out what new products they need and what new products are out in the market. We ask them what changes we should make to meet their needs,” Sam explains. “For example, we had a customer who was stamping parts, and with the regular metal we were supplying, they were only getting 60% yield. So, we went and tweaked the chemistry and mechanical properties with the help of the steel mill, and we were able to increase the yield to 95%. The bottom line is that we make an effort to listen to our customers and suppliers to figure out what is most relevant in the marketplace.”

Domestic operations

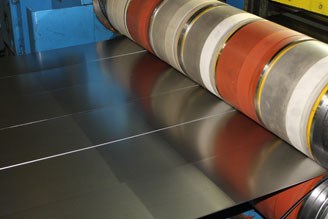

RM Creations, an ISO certified company, provides a wide array of stainless and aluminum products to the U.S.A. All sourced from high quality and highly rated mills, the company provides stainless steel coils, sheets, and plates, as well as aluminum coils and sheets to its domestic clients. The company works with the 300 and 400 series stainless steels, which includes 301, 304/304L, 316/316L, 409, 430, and 439, as well as the aluminum series 1000, 3000, 5000, and 6000.

Each of the products offered by the company come from ISO 9001, RoHS, and REACH certified mills.

While coils, sheets, and plates are the most common product types at RM Creations, the company also offers customers the chance to order materials specific to their needs. “We have customized inventory for different customers, and it is all based on the physical and mechanical properties that they require,” says Sam. For example, if a customer requires something with a high yield or a high elongation, the company can provide materials that will meet those needs.

“Our metals are present in a lot of different industries,” relays Sam. “We sell metal that is used in the oil and gas, auto, roofing, aerospace, nuclear, truck and trailer, and construction industries – where they are used to make fasteners, brackets and washers. We try to diversify as much as we can to meet any kind of customer need.”

Stock and release

In addition to being able to meet even the most specific custom stainless steel requests, RM Creations also stores a large stock of inventory at their warehouse locations. “We maintain a diverse supply of materials to make sure we can deliver quickly to our customers,” says Sam. “In order to be close to our customers and where the products are being manufactured, we intend to stock in even more warehouses throughout the U.S.A.”

The company also offers what they call a ‘stock and release’ program for their U.S.A.-based clientele. “To ensure that our customers can get what they need when they need it, we will keep stock of a certain product for a company, and release it to them as they need it,” Sam relays. “This way, we are cutting down extended lead times and allowing the customer to focus on making their product. We act as inventory control for many companies.”

Global operations

The company’s global reach is quite extensive, thanks to its small but dedicated team of professionals. Their export business includes sending different kinds of scrap metals, such as stainless steels, aluminums, copper-based and other metal grades, to countries all over the world.

RM Creations acquires its scrap metals from two different channels. The first manner in which it acquires the scrap is from end-user facilities. These facilities generate scrap after they do process work. Another form of acquiring material comes directly from scrap yards, who collect it from the general population. “If we acquire the metal from an end-user facility, it is usually after they have cut the metal to fit their needs, and it just becomes leftover metal that they need to get rid of. If we are getting the metal from a scrap yard, it can be any grade and type of metal, in all shapes and sizes,” says Chait. The quantities of scrap they acquire are in the thousands of metric tons monthly.

When RM Creations exports to other countries, there are several different types of customers they sell to. “Various steel mills tend to buy a lot from our company,” explains Chait. “They will take the metal, melt it, and start the process of making plates, coils, etc. Then there are smaller-sized foundries that take the scrap back to their foundries, and make use of the scrap materials. Our third customer type would be those who take the scrap and other mixed metal material and do a lot of hand/machine sorting of the material. These clients then sell the material based on what they have sorted.”

The company focuses their export efforts on countries that have a need for this kind of material, “Which means we do a lot of business with South and Far East Asian Countries,” Chait relays. “Each country has a unique set of items they handle, and we try to cater to them accordingly.” RM Creations also boasts the ability to meet the custom requirements of the companies they export to globally. “We try to be customer friendly always, which means meeting their requirements. Some mills overseas require very tight packaging of the scrap metals, while some require very loose packaging. Some may even require a specific size of scrap. We supply what they need,” he continues.

The list of companies and countries that RM Creations works with changes all the time. “There are different tariffs and duties that apply to imports and exports, and those are constantly changing. This impacts who we are buying and selling to on any given month,” Chait explains.

Moving forward

In the company’s 34th year of operation, RM Creations continues to put the customers and suppliers first. “Our goal is to continuously better our working relationships with our customers and suppliers,” says Sam. “We stock metal, but I think what is more important is making sure our materials arrive on time, and we provide the best service possible to those we work with. We want to give them the best experience possible.”

The company has seen a steady 3% to 5% growth in the last few years, despite the market challenges they have faced. “Our plan is to maintain the stable volume of orders we have now. If we can do as well as we did last year, we consider ourselves to be doing well,” adds Chait. “In the future, we may look into other metals such as carbon steel or other copper-based alloys, but for now we are going to keep doing what we are good at.”