Founded in 1925, Nippon Yakin Kogyo (Nippon Yakin) is a Japanese manufacturer of stainless steel specialties with a long history. Currently, the company manufactures and supplies strips and plates for a wide range of materials, from general-purpose stainless steels (such as type 304 and type 316L) to high-performance materials (such as super stainless steels and Ni alloys). In particular, the company sells more than 10,000 tons of Ni alloy flat products annually, and in recent years has maintained a position among the top three in the world.

By Charlie Evans and Kiyo Ichikawa

Recent Developments at Nippon Yakin

Appointment of New President Shigemi Urata

At the general shareholders’ meeting on June 26, it was decided that Shigemi Urata (former director) will be appointed as the new President. The change in President comes as a result of the completion of various measures, including large-scale investments during the five years that former president Kubota, who became the new Chairman, was in office. From now on, the medium-term management plan 2023 and other measures will be implemented under the new president Urata.

About the Medium-Term Management Plan 2023

Considering various changes in the unpredictable business environment, Nippon Yakin has compiled and launched the “Medium-Term Management Plan 2023,” a set of measures to be undertaken and implemented over the three years from fiscal 2023, in order to achieve resilient and sustainable growth beyond its 100th anniversary in 2025 and into the future.

The goal of the “Medium-Term Management Plan 2023” is to “pursue ‘diversification of products and raw materials’ and contribute to the future of the earth as a top supplier in the nickel alloy and stainless steel market,” and has set the following three basic strategies:

- Develop and provide industrial materials that pursue increasingly sophisticated market needs and create new value

- Establish a production system that enhances technological superiority and responds to changes in the market environment

- Establish a sustainable management base that will not waver even in environmental changes

Major measures include:

- Expanding sales of high-performance materials in growth areas and target markets

- Expanding product items by deepening and expanding alliances, mainly with a joint venture in China

- Developing and establishing manufacturing technologies that will enable stable increased production of a variety of high-performance materials

- Securing superiority in future manufacturing technologies that contribute to carbon neutrality (carbonless nickel smelting, and more.)

- Planning and executing human capital, research and development, and capital investment plans from a medium- to long-term perspective, and so on.

Status in FY2023

In the stainless steel industry, demand increased due to the recovery of production of transportation equipment such as automobiles, but overall remained sluggish due to inventory adjustments for semiconductor manufacturing equipment and delays in the start of construction projects.

As for high-performance materials, the environment and energy fi elds, including flue gas desulfurization equipment for thermal power plants in India, showed solid trends. Inventory adjustments also progressed in the durable consumer goods sector, including sheathed heater materials and bimetal materials for home appliances. However in the second half of the year, project postponements were repeated due to a downward trend in the LME nickel market and the stagnation of the Chinese economy, resulting in sluggish demand overall.

In response to this external environment, Nippon Yakin shifted to a production system in line with demand while steadily implementing the measures outlined in its “Medium-Term Management Plan 2023,” securing appropriate roll margins and implementing thorough cost reductions. As a result, although sales volume decreased by approximately 23% compared to the previous fiscal year, the company achieved a profit of 13.6 billion yen (non-consolidated).

Sales Expansion of High Performance Materials

Nippon Yakin has a wide range of high-performance materials, including corrosion-resistant materials, heat-resistant materials, and thermal expansion control materials. By developing and capturing demand through solution sales, these high-performance materials are used in various fields, taking advantage of their respective characteristics. Here are some topics regarding sales expansion of high-performance materials.

High Performance Materials in the Hydrogen Energy Field

Hydrogen, which does not emit CO2 when used, is attracting attention as an energy source that will lead to decarbonization, and efforts to create a hydrogen value chain (hydrogen production – transportation – storage – use and consumption) are progressing worldwide. Currently, fossil fuel-based reforming methods are the mainstream method of producing hydrogen. In recent years, technological development and commercial operation of a water electrolysis process that generates hydrogen by electrolysis of water has been considered. As water electrolysis processes, alkaline water electrolysis and proton exchange membrane water electrolysis are being considered, but alkaline water electrolysis, which applies salt electrolysis used in caustic soda production, is being commercialized because it allows stable and large-scale hydrogen production. Pure Ni is used as a component in terms of its alkaline resistance and electrical properties. Nippon Yakin has traditionally supplied many sheets and strips of pure Ni for the electrolysis of salt water in caustic soda production. As its quality has been recognized, its use in alkaline water electrolysis processes is also on the rise.

Hydrogen produced by electrolysis of water using electrical energy that does not generate CO2, such as solar power generation, is attracting attention as green hydrogen. Solar power generation is a power generation method that directly converts light energy into electricity using solar cells. Semiconductors made of polycrystalline silicon are used for solar cells. The Siemens process, a typical method of producing polycrystalline silicon, includes a process under high temperatures and high pressure conditions. The highly heat-resistant Ni alloy UNS N08810 is used in the reaction vessel for this process. Steady demand is expected in the future, mainly in China and other Asian regions.

The fuel cell vehicle field is one of the fields in which practical application and commercialization of hydrogen utilization is progressing. Hydrogen stations that supply hydrogen, the fuel for fuel cell vehicles, are in a high-pressure hydrogen gas environment, which creates a high risk of hydrogen embrittlement (a phenomenon in which materials become brittle when exposed to a hydrogen environment). For this reason, there are some parts that cannot be used with normal type 304, and improved type 316L, which has improved hydrogen embrittlement resistance through optimization of the components, is used. A heat exchanger using Nippon Yakin’s improved type 316L won the silver prize in the 2017 Award for the Best New Applications featuring New Technology from ISSF (now worldstainless) and the top prize in the 16th Stainless Steel Association Awards from the Japan Stainless Steel Association, and there is expected demand for it to continue to grow for hydrogen stations both in Japan and overseas.

Various technological developments are progressing in the hydrogen-related field, and it is expected that this field will have a high possibility of new applications and demand in the future. Nippon Yakin is working to capture needs by understanding industry and technology trends and collecting various information, mainly through the Solution Sales Department. In addition, in the “Mid-term Management Plan 2023,” Nippon Yakin plans to establish a new material evaluation test facility in a hydrogen environment, with the goal of completion in fiscal 2025. Nippon Yakin hopes that this test facility will contribute to accelerating the application and adoption of existing materials in the hydrogen environment field and the development of new materials.

Expansion of High Ni Alloy Product Items Using Chinese JV

Nippon Yakin is also working to expand product items using Chinese JV, with a focus on expanding sales of high-performance thick plates to China. Using the wide-width hot rolling machine of Nanjing Iron and Steel Co., Ltd., with which it has a cooperative relationship through its joint venture Nisco Nippon Yakin Kogyo Nanjing Co., Ltd., Nippon Yakin successfully manufactured wide-width plates of high heat-resistant Ni alloy UNS N08811, 25 mm thick and 3270 mm wide, in 2020, and wide-width plates of high corrosion-resistant Ni alloy UNS N10276, 50 mm thick and 3900 mm wide, in May 2023. These high heat-resistant Ni alloys and high corrosion-resistant Ni alloys have high strength at high temperatures and are difficult to hot roll, but by utilizing the know-how Nippon Yakin has cultivated with the cooperation of Nanjing Iron and Steel, Nippon Yakin has succeeded in manufacturing wide-width plates.

For the highly corrosion-resistant and heat-resistant Ni alloy UNS N06625, plates with a thickness of 50 mm and a width of 3,500 mm were manufactured in 2021, and after further consideration for further thinning, an ultra-wide plate with a thickness of 15 mm and a width of 3,100 mm was recently successfully commercialized. There are only a limited number of manufacturers in the world that can supply wide plates of this alloy, therefore Nippon Yakin will be expanding its lineup of competitive products. By widening the width of the plate material, the number of welds can be reduced in the pipe manufacturing process for natural gas projects, and the benefits of reduced construction costs and shorter delivery times are expected. The product is already being sold in the oil & gas field, and demand is expected to continue in the future.

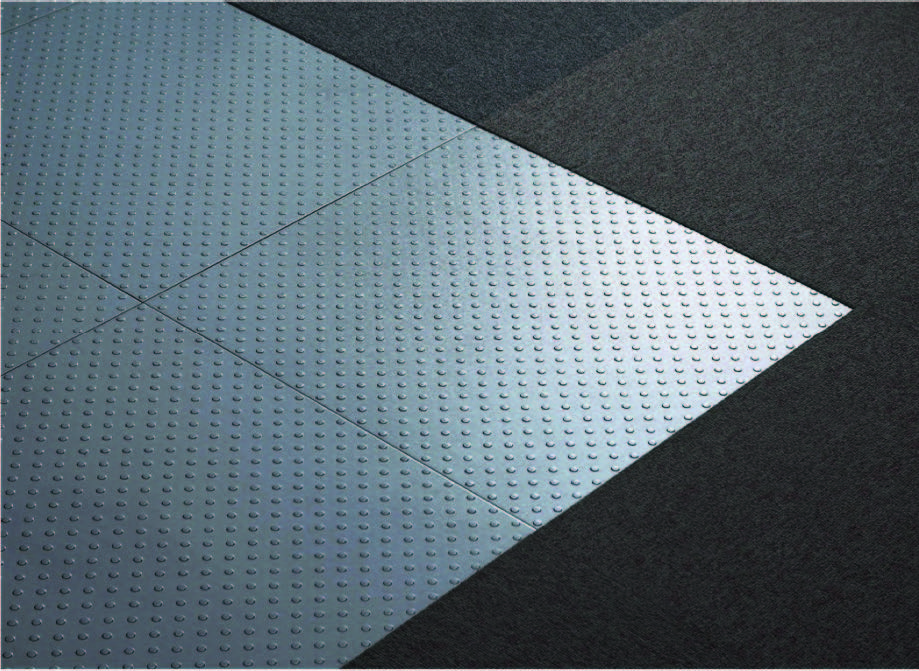

POLKA PLATE, a Stainless Steel Floor Plate with Polka Dots, Wins Gold Award at the Stainless Steel Industry Awards 2024

Nippon Yakin also supplies high value-added stainless steel as an attractive product. POLKA PLATE, a representative high-value-added material, won the Gold Award in the Market Development category at the worldstainless Stainless Steel Industry Awards 2024 on May 23, 2024.

POLKA PLATE is a type 304 stainless steel floor plate with polka-dot protrusions (convex parts). Its excellent anti-slip properties have been rated R13, the highest rank, in the German Industrial Standards slip resistance test (DIN51130). Compared to checkerboard patterned plate, the convex parts are rounded, so when sweeping, dirt and water are less likely to remain, and it has excellent cleaning and drainage properties. For this reason, it is used for factory floors, stairs, stages, and more. In the food, cosmetics, pharmaceutical, and other fields, and in 2022, there was also an example of the use of 130 ton POLKA PLATE in the cosmetics field. In addition, experiments have demonstrated that the polka dots can be moved with less force than checkerboard patterned plate and that they also make less noise when moving, and their use is being expanded to include box truck floors, commercial elevator floors, medical facilities, and more. In addition, because the polka dot pattern gives a soft impression, they are also working to capture demand in commercial facilities and department stores where design and aesthetics are required. This award was given in recognition of Nippon Yakin’s efforts to develop markets in addition to the traditional uses of stainless steel floor steel sheets.

Overseas Exhibition Activities

Since 2004, Nippon Yakin has been participating in overseas exhibitions, mainly through local subsidiaries and the Solutions Sales Department, to increase its recognition overseas, develop new customers, and strengthen relationships with existing customers. Due to the effects of the COVID-19 pandemic, exhibition activities were suspended for a while, but they resumed booth activities at Heat Exchanger World Americas 2022, held in Houston, USA in November 2022, and realized how effective face-to-face meetings are.

In 2023, Nippon Yakin exhibited at Stainless Steel World Expo 2023 (held in Maastricht, the Netherlands) in September, where a booth was set up with Nippon Yakin Europe Limited (Nippon Yakin’s European subsidiary), held business and technical meetings with customers from Europe, Asia, and America, and also made contact with new customers. In October, Nippon Yakin participated in Heat Exchanger World Americas 2023, where a booth was set up with Nippon Yakin America, Inc. (Nippon Yakin’s US subsidiary), and made contact with existing and potential customers in the North and Central America area.

Nippon Yakin plans to exhibit a booth at Heat Exchanger World Americas 2024 to be held in October this year. This year’s exhibition will be held closer to downtown and on a larger scale than the 2023 event, so Nippon Yakin hopes to make contact with even more customers. In addition, regarding the hydrogen-related field, which is one of the focus areas, they plan to have booth activity centered around Nippon Yakin Europe Limited at the Hydrogen Technology Expo to be held in Hamburg, Germany in October this year. Furthermore, in November, they plan to exhibit at the first booth in the Middle East region at ADIPEC (Abu Dhabi International Petroleum Exhibition and Conference), one of the world’s largest energy industry exhibitions, to be held in Abu Dhabi, United Arab Emirates.

Final Words

Nippon Yakin will continue to expand its high-performance materials business, and aim to continue to be trusted by customers with industry-leading quality, delivery time, cost, and solution proposals in order to be a sustainable company in the future, including its 100th anniversary in 2025 and beyond.