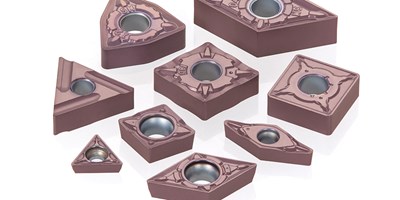

Tungaloy, a company with centers across the globe in North America, Asia, and Europe, has unveiled the AH6225 PVD grade insert for machining ISO-M stainless steels. AH6225 significantly expands the application coverage from continuous to interrupted cuts in a broad range of cutting speeds, while maintaining outstanding tool life and reliability in stainless steel turning.

A thick titanium-rich PVD coating with excellent thermal stability has been developed specifically for AH62225. This coating effectively prevents crater wear from developing on the insert rake surface. The grades top layer incorporates the latest titanium-rich nano-multilayer structure; its high-density crystal orientation enhances the grades hardness for superior wear resistance.

AH6225 also features a dedicated carbide substrate that excels in fracture toughness and thermal conductivity. Improved heat dissipation performance on the cutting edge prevents plastic deformation of the substrate due to thermal stress.

Machinability of stainless steels varies enormously from grade to grade depending on alloy elements, hardness, and manufacturing processes, which significantly influences insert life performance. To address this challenge, AH6225 incorporates the combined dedicated substrate development and the latest coating technology. The new versatile grade provides maximum reliability across a vast range of stainless steel turning applications from finishing to roughing and from continuous to interrupted cuts in all speed ranges, while ensuring long tool life and predictable wear pattern.

Courtesy of Tungaloy.