McJunkin Supply Company may have been the first branch in the family tree but over the next 100 years, heritage companies around the world would be established and grow into what is now known as MRC Global.

By Sarah Bradley and Brittani Schroeder.

“Being the best is what every leader wants for their company,” MRC Global President & CEO, Andrew Lane, said. “We have that. That position is the direct result of a foundation that was formed and strengthened by so many families and individuals over the last century.”

While MRC Global has grown into the largest, global pipe, valve, and fitting distributor in the world, the company’s deep roots might as well be coated in stainless steel thanks to their history supporting the industrial and chemical industries in the U.S. and offshore expertise in the Norwegian Continental Shelf.

A century of leadership in stainless and specialty alloys

In Charleston, West Virginia, one soldier, Jerry McJunkin, returned home after being injured in WWI to a nation head over heels in love with the automobile. The number of registered motor vehicles in the U.S. had ballooned from 1.8 million in 1914, to 9.2 million in 1920. Jerry, an oilman before serving in the military, recognized the opportunity to build a new future supporting the nation’s seemingly insatiable desire for gasoline.

On February 15, 1921, Jerry joined forces with Bernard Wehrle to form McJunkin Supply Company in Charleston, West Virginia.

Within a year of opening the McJunkin Supply Company, the two bachelors made a trip to the Herscher family homestead courting two sisters, who they eventually married. They also met George Herscher, a successful salesman and brother to the new brides. And so, in 1924, McJunkin Supply Company officially became a family affair when George agreed to join the company.

Soon, McJunkin delivery trucks with their bright red fenders became a common and welcome sight in the oilfields of the thriving Appalachian region. Together, the decedents of these three men would help guide the company through the booms and busts typical of the energy industry for the next 85 years.

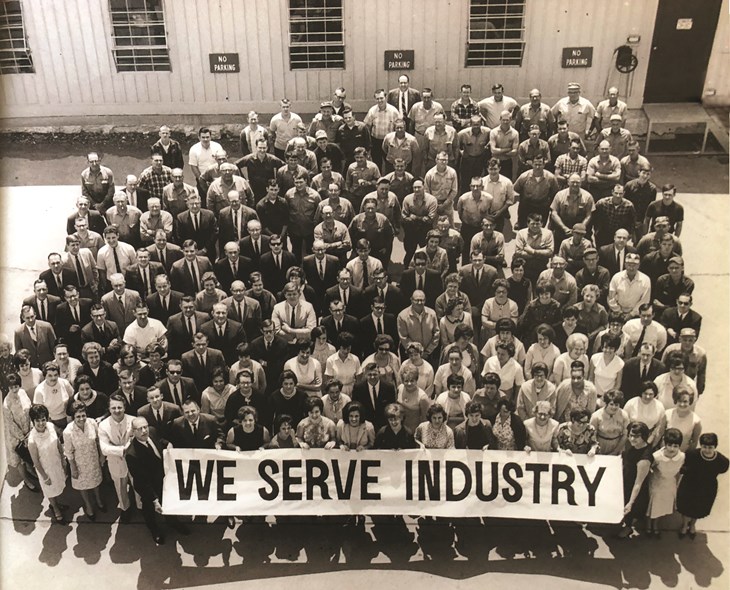

McJunkin managed to rise above the fray created by the highly competitive 1950s by focusing on providing additional value and service to their customers instead of scraping at the bottom of the barrel in price wars with their competition. This value-add approach was only possible thanks to an early commitment to building strong relationships with reputable suppliers.

In 1957, the company sales reached USD $26 million, the equivalent of more than USD $242 million today. Headlines boasting of ‘expansion’ and ‘growth’ filled the newsletters of the period. Pipe, valve, and fitting distribution to oil and gas customers formed the core of McJunkin’s revenues. The company’s inventory and services also began expanding to include material for industrial plants, especially for the chemical industry.

By the late 1960s, industrial and chemical customers would account for approximately 80% of annual sales. McJunkin had firmly established a reputation as the leading supplier for stainless and alloy products in the Eastern U.S. and Gulf Coast. That legacy for technical expertise and service solutions designed for the industrial and downstream sectors would continue when the company became one of the primary pillars of MRC Global.

“Our customers have come to trust MRC Global with these high alloy and exotic products,” John Bowhay, MRC Global’s Senior Vice President – International Operations & VAMI, said. “Our team knows how to react quickly, so our customers get what they need. That is not something that can be taught overnight, it is the result of decades of experience and long-standing relationships developed by working with these specialty mills and manufacturers on a consistent basis.”

A trusted global supply chain

The backbone of MRC Global’s offering is the company’s exhaustive quality assurance program.

“With our quality process, we focus on identifying global manufacturers who can be trusted to produce a consistently high-quality product that matches our customers’ specifications,” Jack McCarthy, MRC Global Senior Vice President – Supply Chain Management, said. “Then, we invest in the relationship with regular site visits, audits and long-term planning. So, when an emergency re-quest comes in, we have an established base of reputable sources who we know very well and can rely on.”

The company credits its proactive quality process, versus relying solely on after-the-fact product inspections, as the reason they are able to consistently provide high quality options to their customers in a timely manner – even with rare materials.

“Our quality process is the best I have ever seen,” said Kim Shelton-Brown, MRC Global Senior Director of Stainless & Alloy Products and 30+ year steel and specialty material veteran. “And everything runs through our audit process. Plain 300 series stainless and all special alloys manufacturers are subjected to the same level of scrutiny.”

The resulting MRC Global Approved Manufacturer List (AML) is so well respected that many of the company’s customers have adopted it as their own for all of their sourcing considerations.

“We are constantly developing additional sources for the products our customers need but we have a very high standard for inclusion on our AML,” Mr. McCarthy added. “It is extremely important that our AML process is rigorous, robust and reliable, so that MRC Global can consistently supply world class products to our customers.”

Currently, the company offers stainless steel and alloy valves from ¼” through 24” 600# in a wide variety of combinations. MRC Global also stocks instrumentation tubing, pipe, fittings and flanges from ¼” through 24” in varying alloys including 300 series (T304/L, T316/L, T317/L, T321/H, T347/H), nickel alloys (Alloy 20, C276, Alloy 400), duplex, super duplex, 6% moly, titanium and Chrome Moly (5, 9 and 11).

Expertise and service you can rely on

At 7:30 a.m. on a Friday, Mrs. Shelton-Brown answered an unexpected call from William Paden with Ascend Performance Materials. It was urgent.

Mrs. Shelton-Brown normally worked with Mr. Paden to manage Ascend’s Approved Manufacturer List at the corporate level. An Ascend manufacturing asset was undergoing a major overhaul when they realized that they did not have the pipe they needed to build the furnace baskets vital to the maintenance work they had planned.

Ascend needed the product, and they needed it yesterday.

Mrs. Shelton-Brown and Mr. Paden discussed options and technical requirements throughout the morning.

The MRC Global Supply Chain Management team considered any and all sourcing options to help Ascend meet their shut down goals. Once they decided on an acceptable solution, Mrs. Shelton-Brown turned the effort over to the Mobile, AL branch manager and operations team.

The official purchase order came through at 8:35 p.m. on Friday evening.

And the branch delivered the product safely on Monday morning at 7:30 a.m. to Ascend’s local fabrication shop.

“We could not ask for better customer service,” Mr. Paden said. “We needed something out of the ordinary and I called Kim knowing that she would know what MRC Global had on the shelf and what else would be readily available in the market. MRC Global made sure we got what we needed, and because of that quick turnaround, we were able to move twice as fast on our maintenance project.”

“Sourcing specialty products requires a great deal of market knowledge,” FT Graff, Vice President – Supply Chain North America, said. “To find the right product, in the right amount from a trusted source is challenging if you do not know who all of the available players are for each specific, special alloy. Luckily for our customers, our team is world-class. We know the market, and by mixing that knowledge with our deep inventory, it makes solutions like that possible.”

About MRC Global

MRC Global is the largest distributor of pipe, valves and fittings (PVF) and other infrastructure products and services to the energy industry, based on sales. Through approximately 230 service locations worldwide, approximately 2,600 employees and with nearly 100 years of history, MRC Global provides innovative supply chain solutions and technical product expertise to customers globally across diversified end-markets including the upstream production, midstream pipeline, gas utility and downstream and industrial. MRC Global manages a complex network of over 200,000 SKUs and 10,000 suppliers simplifying the supply chain for its over 12,000 customers. With a focus on technical products, value-added services, a global network of valve and engineering centers and an unmatched quality assurance program, MRC Global is the trusted PVF expert.

Visit www.mrcglobal.com/100years to learn more about the moments that mattered to the people who built a single, unified future at MRC Global.