Nuclear energy is expected to play a key part in providing for future energy needs. To help further develop this energy source, new safer technology like molten salt reactors (MSRs) have been much explored in recent years. MSR’s are a class of low-pressure liquid fuel nuclear fission reactor where the primary nuclear reactor coolant or fluid is a molten salt mixture.

Stainless Steel World Americas had the pleasure of speaking with Ken Armijo, Lead Researcher at Sandia National Laboratories, to learn about the company’s advanced molten salt valve, which can be employed in future reactors, its capabilities, and what this means for the future of energy testing and production.

By Sara Mathov

Ken Armijo, a lead researcher at Sandia National Laboratories, has always been passionate about engineering. He constantly leverages his education (Bachelor’s Degree in Mechanical Engineering, and PhD from the University of California, Berkley) to innovate existing industry technologies for a better, more sustainable future. In his current role as a Lead Researcher, he explained the various components and processes involved with a new technology, the use of molten salt. “I am a Systems Engineer at Sandia’s National Solar Thermal Test Facility, one of the many labs that is part of a greater impact effort,” said Armijo. “I lead our molten salt and alkaline metals experimental research, specifically as it pertains to industrial process equipment, transport systems, concentrating solar power, and nuclear energy technologies, as well as some fossil energy applications.”

A typical working day for Armijo includes fundamental research, along with modeling and simulation of thermal, hydraulic, and thermal mass transport systems, particularly for valves, pumps, and thermodynamic systems. “Understanding how valves, pumps, and different components can fit in small scale test loops (along with the research being done in a number of labs, both here in the U.S. and abroad) is the main bulk of what we do,” said Armijo. “We are also equipped to do experimental research with molten salt testing to push the limits of technology to higher temperatures.”

What is Molten Salt?

Molten salt is a material that is used as a cooling fluid within Nuclear Energy applications as well as in thermal energy storage. Its ability to absorb, transport and store thermal energy at high temperatures affords it many applications for reducing costs, while improving performance of power systems. The current research by Armijo and his team, investigates the employment of salts such as chlorides and fluorides to increase operational temperatures beyond 600°C to further promote even higher efficient power systems.

Testing and Applications

The Sandia National Solar Thermal Test Facility is where solar tower testing takes place. “This is mostly used for Concentrating Solar Power applications, as well as for aerospace, where we can validate and simulate high temperatures for power generation and high-flux re-entry conditions respectively,” said Armijo. This facility also includes an industrial-scale molten salt test loop, which is a unique facility that demonstrates thermal storage components at power-plant scales before building entire solar power plants,” said Armijo. “The main objective is to advance solar power-generation technology by being able to test multiple components in various conditions before investing large sums of money.”

“We also feature certain molten salt and valve test systems, so we can assess the quality of the components, as well as materials compatibility testing,” explained Armijo. “The molten salt test loop features three different loops and is globally very unique. You can actually test at the lower end of an industrial process scale, various pumps, valves, sensors and other components. This helps qualify different components.”

“We can also do materials compatibility assessment under flow. Our molten salt test pots can test materials either submerged in the salt, or in the vapor space, where we actually have found a lot of materials reliability concerns,” he said. “If you have any evolved impurities, such as hydrochloric acid or hydrofluoric acid, those things can deteriorate and impact the performance of a thermal hydraulic component such as a valve or pump. Over time, it can even cause safety concerns when it comes to gaskets and seals.”

Stainless Steel and Material Selection

Testing is also done with various materials, including stainless steels, nickel-based alloys, and even assessments of welds. “We can see corrosion that occurs with different molten salts and also alkaline metals, such as sodium, that could be problematic for different systems,” said Armijo. “We also are investigating advanced materials. We are considering cost-reduction solutions using stainless steels to help reduce the financial burden from that of ex-pensive nickel-based alloy valves and pumps, which are also difficult to fabricate whenever you are machining them. With stainless steels, you can machine the form factor and apply a cladding or weld overlay to coat the stainless steels that are ASME rated, and they can now operate properly.”

“In general, as the temperature of different components heat up, their over-all strength decreases. All valve bodies and other components have to conform to the American Society of Mechanical Engineering (ASME) Boiler Pressure Vessel Code standard in order to be credible and put out into the market. As strength decreases as a function of temperature, stainless steel still maintains its strength at a sweet spot between 700-800°C. Multiple industries, such as concentrating solar power, nuclear energy, fossil energy, and hydrogen production, are interested in these materials,” he said. “We also look at material degradation to test corrosion rates of different materials and see where we could down-select materials, not just in terms of strength, but corrosion, and cost. That way, a company is not selling very expensive equipment that is not going to be purchased, especially when you require multiple or large valves in a system.”

Stainless steels are often used in these facilities because of its corrosion mitigation properties for nitrate molten salts. “You tend to lose mass when a material is in the presence of a halide salt, as chrome or other ions can leach out from the material into the salt itself. This can lead to stainless steels loosing mass and becoming embrittled,” he said. “Brittle materials break down and do not have the strength needed, especially in high-temperature applications. This makes cladding and coatings another interesting area of research, to mitigate not only corrosion but also leaching of elements, which could be a huge step in molten salt for valves and pumps.”

Different grades of stainless steels are tested and compared for different systems. “We look at grades as a function of their alloy composition, elemental com-position, and we work with companies that modify these, so they can produce materials with different features and compatibility, not just with one particular type of salt, like chloride molten salt, but per-haps even fluoride molten salts, which the nuclear energy industry is interested in.”

The supply chain has also been a challenge for material selection, particularly for procurement of stainless steels. “Some grades have been worse than others. 347H, which tends to have the highest strength, is also the hardest to obtain. 316 is much better, and 304 is the best for availability and cost. At lower temperatures, you generally will see a big disparity in grades, so the added cost and wait time is worth it, whereas in higher temperatures, it might make more sense to go with something in the middle such as 316.”

Energy Transition – Looking Ahead

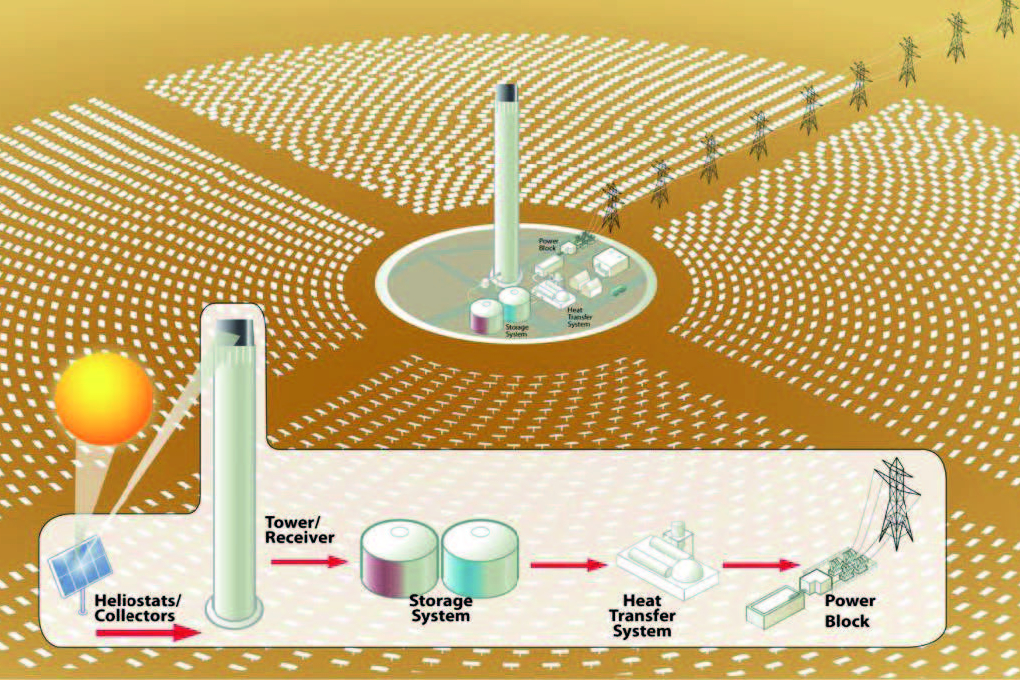

“Sandia is at the forefront of renewable energy. Our U.S. National Labs are leading the charge with concentrating solar power,” said Armijo. “This is different than photovoltaics, where sunlight is incident on a solar panel and electrons come out. The way our concentrating solar power facility works, solar energy reflects off of mirrors onto a solar receiver. The receiver is the bank of tubes with heat-transfer fluid, such as molten salts, falling particles, or supercritical gases that absorb thermal energy, and then process that thermal energy to two storage tanks. These tanks can store heat for up to 16 hours of thermal energy storage, which could be discharged into a heat exchanger, and subsequent power block. Concentrating solar power has been touted as a really good technology for this kind of work,” said Armijo.

The company is also doing particle research, looking at fi ne particles that were originally used in fracking. “We found a new application for them because they can go to temperatures above 1,000°C. They fall through from a top hopper to a bottom hopper where the sun hits the middle test section and they can then be stored,” he said. “One benefit to this, is there is no freezing or significant issues, as there can be with molten salts or alkaline metals. They can also be easily transported with pumps. So, we are looking at several novel technologies, in addition to molten salts. We are really pushing the envelope because as you increase the temperature of thermodynamic processes, efficiencies get higher. If that is higher, overall performance can go up and you can get more electricity,” explained Armijo.

Going forward, several ways of producing energy will still be used, according to Armijo. “All of the technologies will have to work together. Wind is generally better at night, solar is better during the day. But what is really innovative is thermal energy storage technologies, which will make a significant difference as renew-able energy sources become more popular. Right now, I think solar thermal is one of the best because we can store thermal energy for up 16 hours, which no other renewable technology can really do at this point. As different renewables figure out how to leverage energy storage and power production on demand, that will be the key difference,” he concluded.