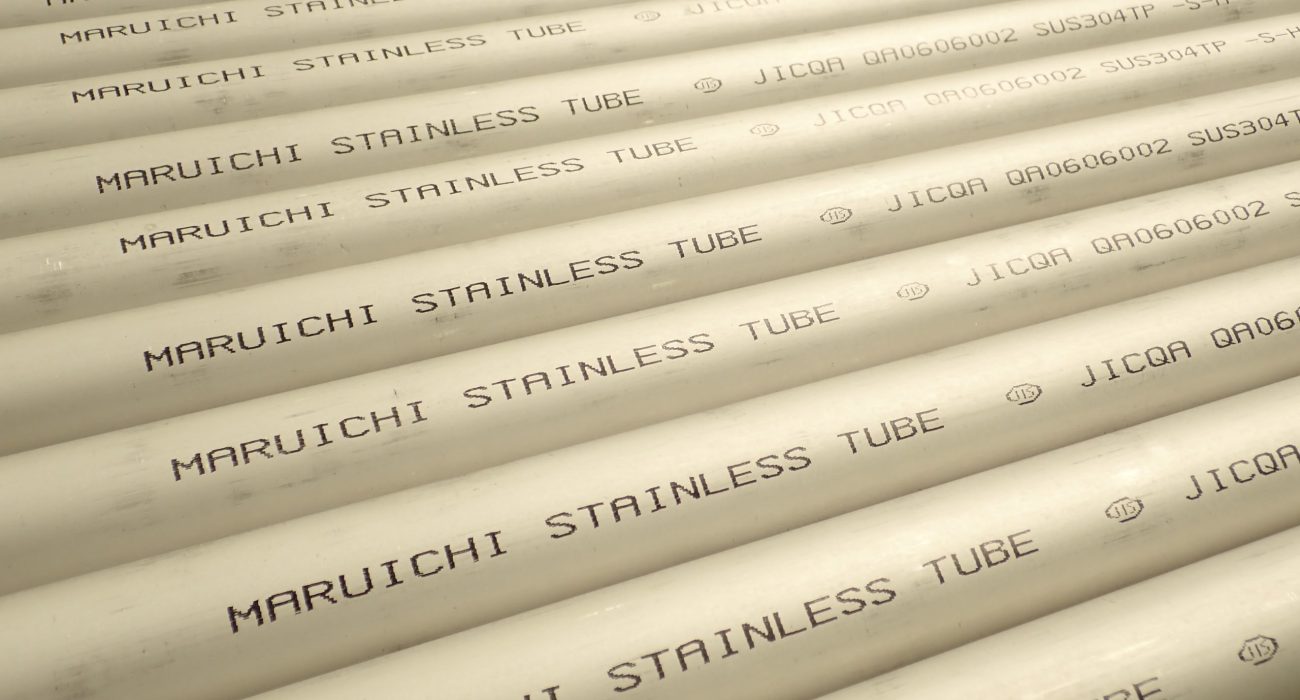

Maruichi Stainless Tube Co.’s (Maruichi) strategic blueprint converges in an upward direction. The company’s growth is unprecedented and, it appears, limitless. Specializing in the manufacture of high-performance stainless steel pipes, tubes, and coil tubes for demanding industrial applications, Maruichi’s decisive progression and definitive expansion drive the company’s success.

In June 2025, the company welcomed Yasutsugu Hayama as Maruichi’s new president. Stainless Steel World Americas welcomed the expansive overview provided by Mr. Hayama concerning the company’s ongoing successes, meticulous strategy, and its plans to incorporate innovations that advance decarbonization.

By KCI Editorial

Responding to the Semiconductor and Automotive Demand

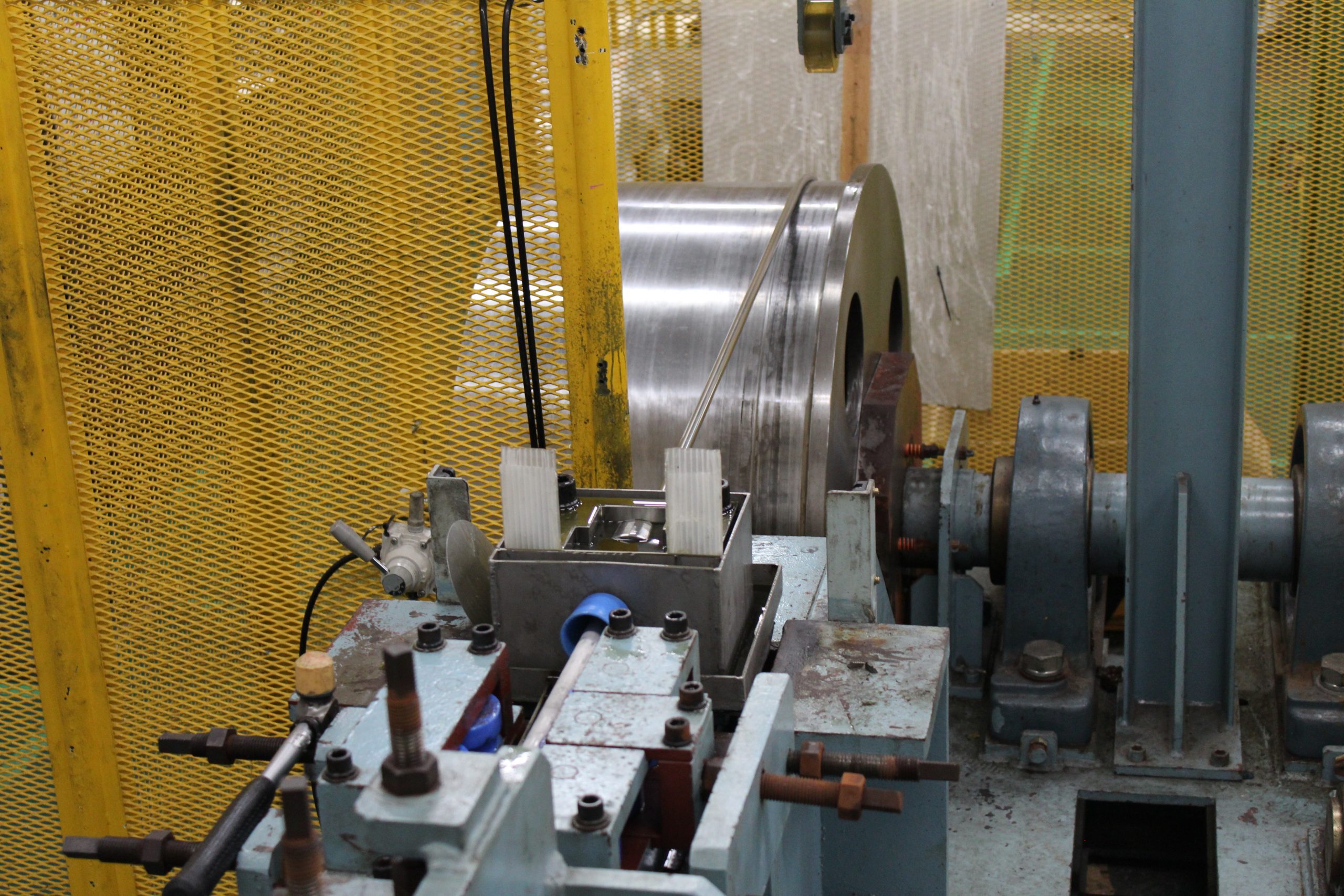

Bright annealed (BA) tubes are vital components in semiconductor manufacturing equipment. As global demand for semiconductors increases, so does the demand for BA tubes. Maruichi has responded to this need by investing significant capital to expand its domestic production capacity to 250,000 tubes per month, a substantial increase from the 150,000 BA tubes they currently manufacture each month.

The company anticipates a market rebound in the near term, driven by renewed demand from the semiconductor and automotive sectors. “While there has been a temporary market slowdown—partly due to geopolitical factors such as the US administration transition and ongoing trade tensions between the US and China—we expect a recovery in 2026, supported by the rollout of government subsidies,” said Mr. Hayama.

The semiconductor sector is a key strategic growth area for Maruichi. “For many years, we have supplied clean pipes and EP mother pipes to semiconductor manufacturing facilities, establishing longstanding, committed relationships with our users,” continued Mr. Hayama. “In recent years, we have expanded both our production capacity and product size range. Our steadfast customer relationships compel us to swiftly respond to the growing demand for high-quality gas piping in semiconductor fabrication. By aligning our development, manufacturing, and sales teams—and working closely with our users—we aim to play an active role in reinforcing the semiconductor supply chain.”

Establishment of BA Tubing in the US

Recognizing the large number of semiconductor fabrication plants under development in the United States, Maruichi established Maruichi Stainless Tube Texas Corporation in 2022 to manufacture bright annealed (BA) tubing. The Texas operation, which employs approximately 120 people, facilitates the semiconductor industry’s emerging supply chain and reinforces the demand for high-quality products and responsive service molded to customer specifications. The automotive sector is the second-largest application area for BA tubing after semiconductors, and Maruichi forecasts that demand for this product will continue to be robust. “We anticipate a gradual shift in demand for our fuel rail piping—used in direct injection engines—toward electric and hydrogen- powered alternatives such as battery electric vehicles (EVs) and fuel cell vehicles (FCVs),” said Mr. Hayama. “However, while EV and FCV adoption is increasing, a sudden decline in internal combustion engine vehicle production, including hybrids, is unlikely in the near term.”

The Stainless Steel Project

As a subsidiary of Maruichi Steel Tube Group, Maruichi Stainless Tube “Stainless Steel Project” is an integral piece of the progressive 2030 strategy. The project involves expansion into the semiconductor sector, as well as the successful extension of its production capabilities to support its commitment to decarbonization. A capital investment of approximately USD352 million is the largest in the Group’s history and includes the construction of two manufacturing facilities in Japan.

Construction began in May 2025 on the 258,000-square foot welded pipe plant, which is expected to be operational in 2027. The plant is situated alongside Maruichi Stainless Tube’s head office. Upon completion, the plant is projected to produce a monthly output of 1,500 tons.

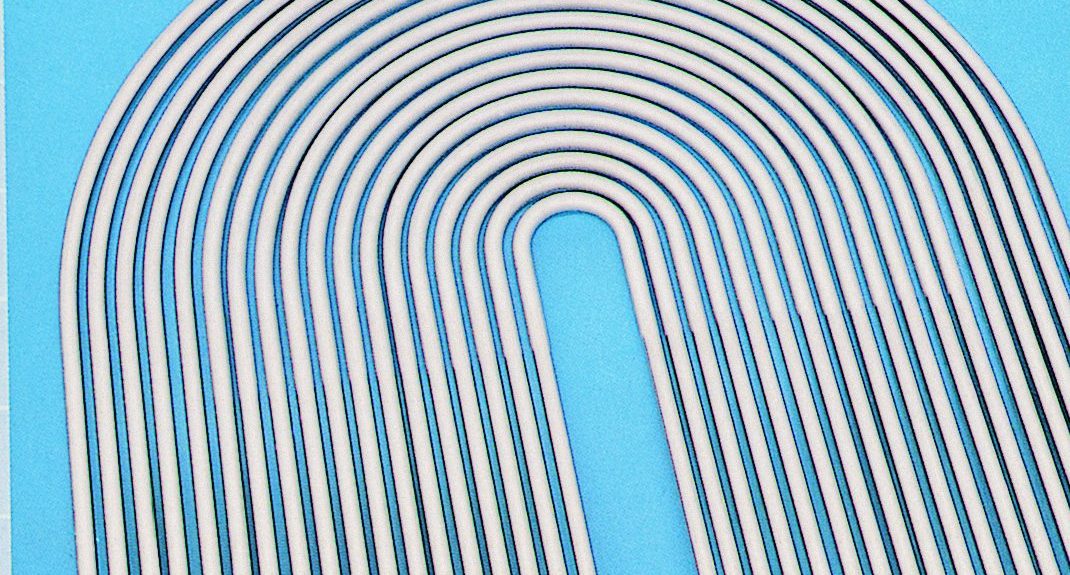

The seamless pipe facility is expected to be operational in the second half of 2027. The 190,000-square foot facility will also be situated on the same grounds as Maruichi’s head office. It is in this facility that the company will install a 5,000-ton hot extrusion press that will operate in tandem with the pre-existing 2,000-ton press. The addition of this press propels the seamless pipe capacity to 2,000 tons and increases the pipe’s maximum outer diameter to 10 inches from 6 inches. “The 5,000-ton press represents a cornerstone of our commitment to building a robust hydrogen supply chain. With this capability, we will enhance our capacity to meet the growing demand for stainless steel pipes in emerging energy sectors such as hydrogen and ammonia, thereby contributing meaningfully to the transition toward a low-carbon future,” enthused Mr. Hayama.

The company’s rationale behind this investment highlights its tremendous ability to analyze, project, and initiate. “With the expected expansion of the hydrogen supply chain—including infrastructure such as hydrogen refuelling stations and cryogenic tankers— demand for high-performance stainless steel pipe is forecast to rise. Our increased tube diameter capability is a direct response to this trend, supporting applications that require large-diameter tubing for hydrogen transport and storage,” Mr. Hayama explained. “In parallel, the new 5,000-ton press will enhance our ability to process high-nickel alloys such as Alloy 625 and Hastelloy C-276, both of which are critical in environments demanding superior corrosion resistance and mechanical strength. These materials will be essential in meeting the next generation of technical requirements across hydrogen, chemical processing, and advanced energy systems.”

A Dedicated Focus on Alloy 825 and Duplex Coil Tubes

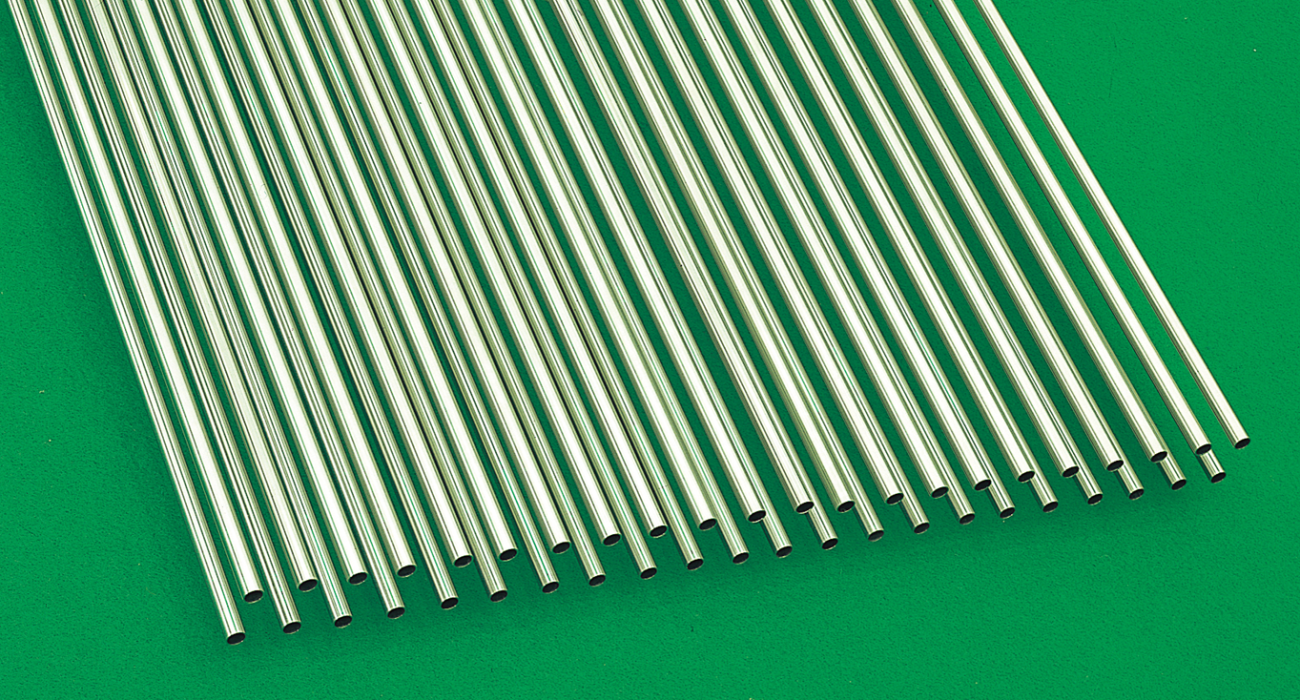

Maruichi’s expansion into the coil tubing market in 2020 was soon followed by exports to the oil & gas and petrochemical sectors in 2021. The company has invested in advanced testing and inspection facilities, ensuring product performance, compliance with industry standards, and fierce dedication to rigorous customer specifications.

“Although we are a relatively new player in the coil tubing market, we are positioning ourselves for strategic growth by focusing on high value and technically demanding materials such as high-nickel alloy 825 and duplex stainless steels,” Mr. Hayama elaborated. “These materials require advanced processing capabilities, and we are committed to delivering the precision and reliability our customers expect.”

Since entering the coil tubing market, Maruichi has seen a consistent volume of orders from major oil companies, including a recent order for an immense project comprising 1.3 million feet of coil tubing.

Investing in Decarbonization

Maruichi has been manufacturing high-pressure stainless steel piping for use in hydrogen refuelling stations for many years. The company supplies piping that is engineered to endure the severest of conditions that exist in a high-pressure hydrogen environment. The result is cold-worked, high-strength 316 series stainless steel tubing designed specifically for applications requiring superior mechanical strength, tight dimensional tolerances, and high resistance to hydrogen embrittlement. Exceptional performance and reliability in these critical systems are the result of the company’s strict adherence to austere quality and safety standards. Reliable delivery of high specification piping has solidified Maruichi’s reputation, and the company’s engagement in hydrogen infrastructure demonstrates its commitment to decarbonization.

A ‘No Sanctuary’ Mindset

Embedded in the company’s strategy is the enhancement of its decarbonization efforts by transforming its manufacturing practices and developing advanced tubing solutions that encompass hydrogen and alternate low-carbon energy practices.

As part of its key objective, the Maruichi Steel Tube Group is strategizing to reduce CO2 emissions by 46% across its operations by 2030 (relative to 2013 levels), aligning with national climate targets.

“As the stainless steel division operates the largest number of heat treatment facilities within the Group, it also accounts for a significant share of our emissions,” explained Mr. Hayama. “This places us in a leadership position to drive emission reduction efforts.” After completing an upgrade to one of its stainless steel tube heat-treatment furnaces in 2022, the company achieved a 10% reduction in fuel consumption. In addition, the installation of solar panels on the office building roof contributed to the company’s transition to renewable energy sources.

“Our initial focus is on reducing Scope 1 emissions — those directly generated by our operations,” Mr. Hayama added. “However, our approach is holistic. We are also preparing to address Scope 2 emissions from purchased electricity and utilities. By pursuing incremental improvements across all areas of the business, we are embracing a ‘no sanctuary’ mindset — where no opportunity for emission reduction is overlooked.”

The KRSA A31 Innovation

“Decarbonization remains a central theme in our research and development activities,” Mr. Hayama continued. “While the adoption of zero-emission vehicles — such as fuel cell vehicles (FCVs) and battery electric vehicles (EVs) — is expected to accelerate, internal combustion engine vehicles, particularly petrol-powered models, will continue to play a significant role in the near term. Therefore, improving the environmental performance of petrol vehicles is a critical step toward achieving a low-carbon society.”

To address this, Maruichi developed KRSA A31, a new high-strength stainless steel alloy engineered specifically for fuel rail piping in direct injection gasoline engines. This advanced material enables higher injection pressures, which improve combustion efficiency and reduce emissions. KRSA A31’s exceptional strength allows for thinner-walled tubing, contributing to overall vehicle weight reduction and enhanced fuel economy. The material also supports greater efficiency in component manufacturing due to its improved formability and reduced material usage.

“Of course, we are also looking ahead to the future and new demand for stainless steel pipes in developing energy fields such as hydrogen and ammonia. R&D projects are underway from the perspective of producing, transporting/storing, and using hydrogen. As gaseous hydrogen embrittles steel, and liquid hydrogen has an extremely low temperature of -253°C, materials must be selected carefully. Ammonia can also corrode steel materials depending on the usage environment, so materials used in infrastructure must be carefully selected. We believe stainless steel is one of the leading candidates for solving these problems.”

Ongoing Growth and Progress

Maruichi Stainless Tube continues to demonstrate robust performance in the global market, with notable increases in both sales and profitability over the past financial year. “Despite ongoing market challenges, Maruichi Stainless Tube delivered a solid performance in 2024, recording sales of approximately USD180 million and an operating profit of USD 17 million,” Mr. Hayama shared. “This reflects an improved return on sales of 9.4%, underscoring the strength of our operational strategy and the continued trust of our global customer base.”

“Looking ahead, we will continue to expand our R&D initiatives to support global decarbonization efforts,” Mr. Hayama concluded. “Our aim is to advance and apply our high-pressure hydrogen piping and high-strength material technologies, driving innovation across both conventional and next-generation mobility platforms.”

Maruichi Stainless Tube’s strategy embodies the company’s maxim: The One-and-Only Company, Found Everywhere. It has positively leveraged itself to successfully facilitate continued innovation and growth, and it shows no signs of slowing down.

In June 2025, Maruichi Stainless Tube Co., Ltd. announced the appointment of Yasutsugu Hayama as its new President, marking the company’s first leadership change in seven and a half years. He succeeds Takashi Onishi, who stepped down as President and as a director and now serves as an advisor after guiding the company through years of steady growth and innovation.

In June 2025, Maruichi Stainless Tube Co., Ltd. announced the appointment of Yasutsugu Hayama as its new President, marking the company’s first leadership change in seven and a half years. He succeeds Takashi Onishi, who stepped down as President and as a director and now serves as an advisor after guiding the company through years of steady growth and innovation.