A proper Asset Integrity Management (AIM) strategy must have provisions for all of a plant’s lifecycle. Traditionally, a maintenance program begins before operation, with the task of preservation and inspection. For most of the lifecycle, the tasks in the maintenance program for new and old plants share many similarities. As time passes however, the maintenance tasks may need to adapt to the aging infrastructure and differences from previous phases of the lifecycle may appear.

By Davi Correia, Senior Mechanical Engineer

Industrial equipment does not age in the way that people are accustomed to thinking of the aging process. If considering a valve for example, a valve is purchased from a reputable manufacturer, with a solid design code, such as API 6D, and often with additional quality requirements. If the valve is preserved properly, the time elapsed since it left the manufacturer has little meaning. Once it has been installed, however, identical valves from the same supplier will age differently, depending on their process conditions, occasional fluctuations, vibration, turnarounds, local atmospheric conditions, etc. Aging is not about how long ago the equipment was purchased or installed, but what it has undergone since. If during commissioning of a new plant, the elastomeric sealing of a valve was damaged by exposure to a chemical used for cleaning or conditioning the piping, then the brand new valve is already old, in the sense that is has deteriorated and is no longer able to contain leakage as a new one could. Conversely, an old valve may still be capable of fulfilling its duties safely. Equipment with unknown histories or for which there is doubt must be treated as old, with a chance of not being fit for service.

Aging is about degradation. After being exposed to operational conditions, the chemical and mechanical properties of the materials used in any equipment will at best remain constant, but most likely degrade. Thus, the assumptions made during the design will no longer be valid; this can occur gradually or instantaneously. This aging process can be seen in piping, vessels and ancillary structures such as pipe racks and valves. However well-specified, it is impossible to predict what processes and surrounding conditions will be like 10 years from now. The new conditions could adversely affect the equipment in ways not considered in original specifications.

Degradation can be caused by several mechanisms, acting isolated or in a combined manner. In fact, plants may have a combination of them in a specific location but not in others. A recent report made by the HSE1 states that the three most dangerous aging mechanisms are corrosion, erosion and fatigue:

Corrosion

is a broad term that includes several distinct mechanisms of degradation. Atmospheric rust needs an exposed ferrous surface, air and moisture. It is a simple, uniform process and the rate of degradation can be fairly predicted. At the other extreme, there is phenomena such as stress corrosion cracking (SCC) or hydrogen induced cracking (HIC), for which specialists still debate over the exact atomic process that leads to failure.

SCC and HIC are much harder to predict and notice than atmospheric corrosion, due to there being no uniform reduction of thickness, and may result in unexpected, catastrophic failure. In between atmospheric corrosion and SCC/HIC there are several other forms of corrosion, such as: microbial, carbon dioxide (sweet), crevice, under insulation, galvanic and pitting.

SCC, in environments containing chlorides, is one of the most common reasons for austenitic stainless steels failure in the chemical and petrochemical industries. SCC can be simply defined as the growth of cracks due to the simultaneous action of a stress and a reactive (corrosive) environment. The required tensile stresses can be in the form of directly applied stresses or in the form of residual stresses. In most cases, the majority of the stainless steel surface will remain free from attacks, but there will be very fine cracks penetrating into the material. SCC develops on the sites of previous corrosion mechanisms – such as pitting or crevice corrosion – and SCC propagation occurs when cracks outpace the rate of corrosion of the initial mechanism. The continuous crack growth may lead to failures ranging from leakages to catastrophic rupture of bolts (see Figure 1). The detection and sizing of these cracks by means of non-destructive evaluation (NDE) techniques is not always possible. Dye penetrant, Eddy Current, and Ultrasonic are some of the common testing techniques used, but different crack orientations and the geometry of the equipment may severely hinder their effectiveness.

Erosion

is a damage mechanism that differs from corrosion, as it is a physical process rather than chemical. Solid particles carried by the process fluid, or the process fluid itself, can impinge on the surface of piping, fittings or equipment and cause loss of material. Its effects may compound with corrosion, when erosion removes some of the protecting oxide layer and exposes the base metal to corrosion.

Fatigue

occurs when a material is subject to a cyclic loading and develops cracks that ultimately lead to failure, often catastrophic. There are many theories for explaining and predicting this aging mechanism, but a consensus has not been reached yet. Fatigue is commonly associated with vibrations and repeated load conditions in equipment such as pumps and compressors. It can also affect piping and structural elements, like civil structures. The stress cycle for piping may originate in the flow conditions and wind may induce cycling in structures.

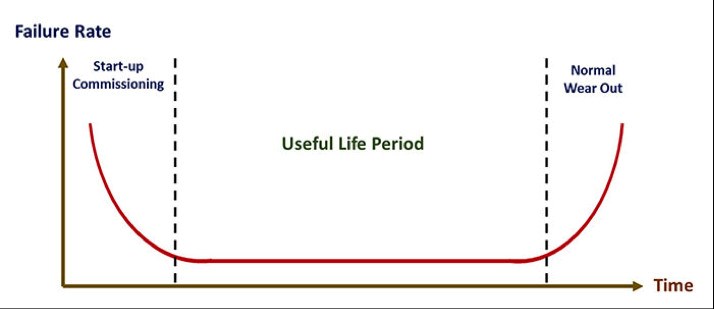

A theoretical model often used to describe how failure rates change over time is the ‘bathtub curve’ (see Figure 2). This model predicts that the failure rate rises during the initial phase of the equipment lifecycle due to factors such as manufacturing defects and bad commissioning. The failure rate is then lowered during normal operation, only to rise again near the end of its design life. This second rise is the result of the natural wear out of components, sometimes compounded from unknown interactions among them.

The model is not perfect, but it serves to illustrate that maintenance needs can vary as equipment ages and approaches its intended life span. Maintenance for aging plants is included in the large scope of Asset Integrity Management (AIM), which is a structured program designed to assure adequate means and resources for keeping the integrity of an asset during its design life. AIM programs vary according to several factors, including industry, government regulations, company culture, etc. At the center, all of the programs share the common goal of developing clear quality procedures related to all phases of a lifecycle: design, procurement, construction, commissioning, start-up, operation, and decommissioning, including support activities like MOC (Management of Change), maintenance, inspection, definition of control KPIs and subsequent monitoring.

AIM programs for aging plants can have some specific challenges. These challenges may include:

Knowledge retention from senior employees.

When employees retire, they take with them part of the plant’s history, which often contains subtleties that are not present in the formal records. Many problems tend to repeat themselves and if time is not taken to train a new generation, there is the risk of ‘reinventing the wheel’ many times over.

Operational procedures may have to change.

Practices allowed in earlier life may now stress the plant beyond safety. Repeated training is required for all operators to get used to the new procedures. This is particularly hard for senior operators, as some tackle the new procedure with the mentality of “But I have been doing the other way all my life!”.

Keeping track of changes in the design codes used in the plant.

Some older assumptions may no longer be permitted under the revised code. It is necessary to discover if the original design is outdated, but still valid, or if a previously unknown mechanism now requires review.

Training to recognize aging mechanisms and their warning signs.

In new equipment, a given corrosion rate may be high but acceptable for a short term. For older equipment, that same rate may be unacceptable due to the accumulated reduction in wall thickness since operation began. Training for the operators needs to address this issue, or plant operators run the risk of failure due to insufficient skill to discern between the ‘old abnormal’ and the ‘new abnormal’.

Review and adaptation of the original hazard identification process.

Are the original assumptions still valid? Has any process modification invalidated them? What aging mechanisms were overlooked? The history of breakdowns, MOC, turnaround and accidents must feed this review.

Inspection frequency must be updated.

In some cases, there may be new techniques that are required to monitor the progress of damage. This is just one of the increases in maintenance costs that must be addressed by the higher management.

Mergers and acquisitions involving old plants require the harmonization of different business cultures and AIM practices.

This is already challenging enough, but if unreliable or incomplete documentation about maintenance and MOC is added to the mix, this a fertile ground for accidents to happen.

Plants age and as they approach the end of their design life, they require more attention and resources. Aging requires a business plan that considers budget increases for maintenance during a period when the plant’s output is normally past its peak. The cost of maintaining or upgrading will keep rising until it reaches a point where it surpasses the financial capacity of the plant to sustain it. If no alternatives can be found, then the moment has come to properly shutdown and adopt the procedures required in safety and environmental regulations to prevent spillages and other accidents.