Global carbon neutrality

The Biden Administration has pledged to cut greenhouse gas emissions in the United States by 50% to 52% (based on levels recorded in 2005) by 2030. The administration has also pledged to reduce emissions to zero by 2050. This is called ‘net CO2’ emissions, but this does not eliminate all sources of CO2. If you consider that humans exhale CO2, the goal of reducing emissions is to benefit humans, rather than cause the extinction of the human race.

China, similarly, is planning for a carbon neutrality by 2060.

Is this bad news for the stainless steel industry? At first glance, it could be. The switch from coal power to wind and solar greatly reduces the opportunity for stainless alloys to be used. However, there is a small bit of irony in that by pushing for carbon neutrality; the result will be coal-fired plants being used, just in different way. They will use different fuels, which will result in a different fate for the CO2 and will create a large increase in stainless steel sales.

Carbon capture and sequestration

There is universal agreement that carbon capture and sequestration process will be needed; however, there are few options to choose from on the market.

There is a direct air process that utilizes potassium chloride as an absorbent. This process would mean a lot of positive revenue for stainless steel companies, but many companies believe the process is too expensive for serious consideration.

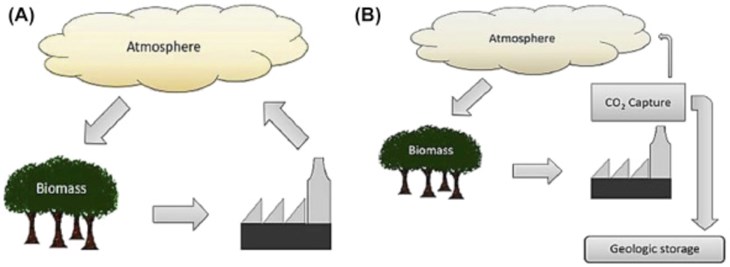

Another option available is considered more practical and is actively being pursued by the United Kingdom. This process is called Bioenergy Carbon Capture and Sequestration (BECCS).

Converting plants to BECCS

The cost of the BECCS approach is greatly reduced by the availability of existing coal-fired plants. Minimal capital investment is needed to switch to biomass. However, potential problems occur if the coal-fired plants are retired and then dismantled too soon, resulting in no leftover plants to convert to biomass.

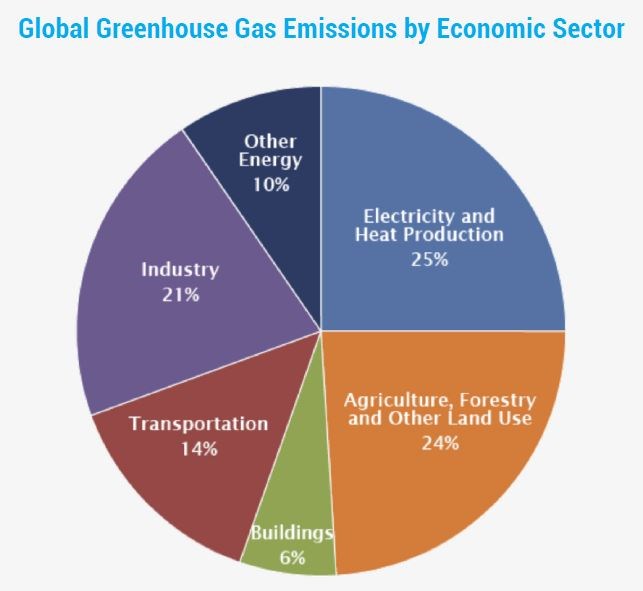

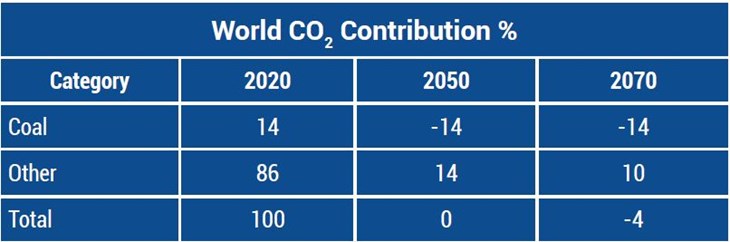

Global energy related CO2 emissions amount to approximately 33 gigatons (GT). Coal contributes 15 GT (or 45%) of total global energy production. If all coal fired plants adopted the BECCS process, they would create a negative 15 GT of CO2 and help offset emissions from other sources. From this perspective, you can see it is very important to not retire coal plants, but instead to convert them to BECCS.

While at U.S. President Joe Biden’s global climate summit, China’s President Xi Jinping said, “China goal is to curb coal consumption in its economic plans over the next 10 years.” Xi also confirmed that China’s existing targets are on track for the reduction of carbon dioxide emissions before 2030, and carbon neutrality before 2060. There has also been a lot of publicity around a Chinese program where inefficient coal plants are being retired and replaced by highly-efficient low emission ultra-supercritical coal-fired plants.

The Institute of Energy, Environment and Economy, Tsinghua University in China has studied multiple options for reducing carbon emissions. The conclusion they have come to is:

With the President Jinping’s commitment to carbon neutrality by 2060, the use and benefits of BECCS would be considerably greater than envisioned in the study. Carbon capture would be several GT of CO2.

It is also important for those companies building new plants to consider technologies that will lend themselves to a cost-effective conversion to biomass.

To address climate change, companies like Sumitomo have developed technologies such as the Flexi-Burn™, which allows circulating fluid bed boilers (CFBs) to operate in either conventional firing or carbon capture mode without significant plant modification. This gives clients the flexibility they need to endure an uncertain regulatory and carbon credit market.

BECCS and stainless steel

Reference

1. Stainless Steel: World Markets published by the McIlvaine Company.

About the author

Robert McIlvaine is the CEO of the McIlvaine Company, which publishes Industrial Valves: World Markets. He was a pollution control company executive prior to 1974 when he founded the present company. McIlvaine oversees a staff of 30 people in the U.S. and China. http://www.mcilvainecompany.com.