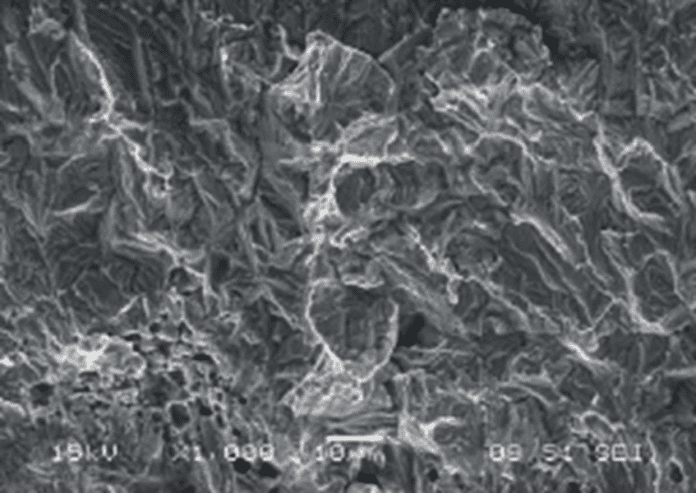

Two 316 stainless steel expansion joints that leaked during service in an emulsifier plant were examined. The two joints were located up- and downstream of a glass-lined reactor that was cycling a process stream containing lubricant additive precursors, and operating at 7 psig, between ambient temperature and 400°F. The objective of the lab analysis was to locate and determine the cause of the leak in the expansion joints. Visual examination, metallography, SEM microscopy, EDS analysis, and OES chemical analysis were performed. The results indicated that the expansion bellows cracked from chloride stress corrosion cracking that originated on the inside surface.

Chloride contamination within the process stream, steam cleanout and exposure to chloride-containing environments during shutdown likely subjected the expansion bellows to aqueous chloride solutions. Residual stresses from cold working also contributed to the damage mechanism.