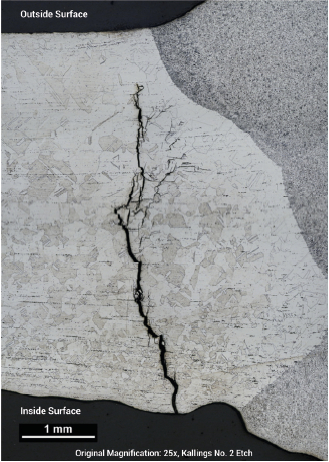

A cracked 2-inch, schedule 80 pipe with a welded-on flange was examined. The pipe was reportedly in service carrying hydrogen, water, and hydrogen sulfide (H2S). The pipe contained a through-wall crack that resulted in a leak. The objective of the lab analysis was to locate and determine the cause of the crack and the leak in the pipe. Visual examination, two types of penetrant examination, metallography, scanning electron microscope (SEM), energy dispersive x-ray spectroscopy (EDS) analysis, and optical emissions spectroscopy (OES) chemical analysis were performed on the pipe. The results indicated that the pipe cracked because of chloride stress corrosion cracking that originated on the internal surface of the pipe adjacent to the pipe-to-flange weld. The pipe and flange were constructed of type 321 stainless steel while the weld was made of type 347 stainless steel. No manufacturing or welding defects or anomalies were associated with the crack.