An evidence based, forecast driven sales approach can maximize profits for stainless steel, pump, and valve companies. There are two variations of the approach based on whether the stainless steel sold for the pumps and valves will be utilized in general or high performance service.

By Bob McIlvaine, President & Founder, The McIlvaine Company

The capital investment and sales decisions are different for the two performance classifications. The evidence needed is also different, with one based on logistics, and the other based on product performance. 1

Stainless steel pumps and valves performance categories are:

- General service

- Severe service

- Critical service

- Unique service

General service includes stainless steel pumps and valves which are purchased based more on cost and delivery, and less on performance. Most general service pumps and valves are not constructed of stainless steel. Severe service includes abrasive, corrosive, high temperature, and high pressure applications. High-cost stainless steel products are often needed. Critical service includes sanitary, and other applications, where performance is important to product quality or safety. Stainless steel is routinely utilized in critical service. Unique service includes special stainless steel pumps and valves designed for a specific customer.

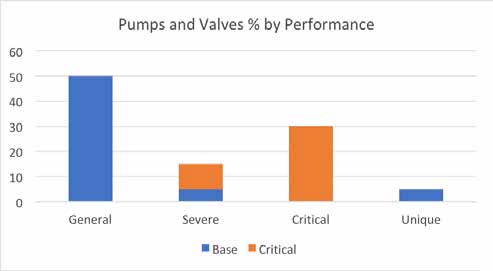

Figure 1 shows the market share percentage for each of the types of pumps and valves. The critical service category excludes critical pumps and valves, which are also in severe service.

Severe service, critical, and unique, are high performance service categories. In high performance service, the performance is more important than price or delivery.

General service includes pumps and valves sold as a commodity. For example, in a food processing plant, the pumps and valves on the municipal water intake pipeline would be in the general category, and not made of stainless steel. The pumps and valves moving food products would however be critical, and they would typically be made of stainless steel. The pumps and valves on the high pressure steam, would be severe service, and would likely be made from stainless.

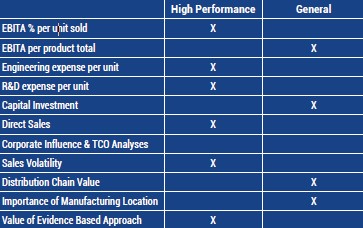

From a profitability strategy perspective, it is advantageous to contrast the high performance and general performance business factors. The comparison in Figure 2 shows which type produces higher results. This applies to the stainless steel manufacturer as well as to the pump and valve supplier.

High performance stainless steel pumps and valves can be sold at higher prices because of their unique qualities. Therefore, high earnings before interest, taxes, and amortization (EBITA), can be achieved for a relatively small number of stainless steel pumps and valves. Many general stainless steel pumps and valves are sold in large quantities, showing that EBITA based on total revenue is higher than for a small niche market.

EBITA can also be increased with lower production costs than the competition. This is more likely with large volume general performance products. Engineering and R&D expenses per unit sold are greater for high performance products, to develop the unique features. Engineering and R&D for general performance stainless steel pumps and valves can also be substantial if the focus is reducing manufacturing costs. But, the cost per unit sold would be low due to the high volume.

Capital investment will typically be higher for general performance stainless steel pumps and valves due to the likelihood that they are produced in a supplier owned facility. High performance stainless steel pumps and valves are likely to include castings and components supplied by others. Sales of high performance stainless steel pumps and valves depend on conveying knowledge of the superiority, so direct sales by knowledgeable individuals is important.

General purpose stainless steel pumps and valves can be purchased with the simple total cost of ownership analysis based on price. The purchase of a high performance stainless steel pump or valve, however, warrants a total cost of ownership analysis. One large company found that local purchases tended to be based on price and experience. This precluded consideration of new and better stainless steel components.

Corporate staff took over the high performance stainless steel pumps and valves decision making for several plants. The result was a considerable reduction in total cost of ownership. A large chemical company has a corporate staff assigned to stainless steel pumps and valves, and strives to take advantage of all the improvements as they occur.

There tends to be volatility in the sales of high performance stainless steel pumps and valves. For example, the market for stainless steel products for fracking fluctuates considerably. The market for the same components used in water intakes in plants, in contrast, is relatively steady. The manufacturing location is also typically important for general purpose products, where freight costs and delivery time are more important than for high performance products.

Importance of Detailed and Current Forecasts

Very detailed forecasts for general and high performance stainless steel pumps and valves are needed. Segmentation of high performance opportunities by critical, severe, and unique, is needed in order to determine the most profit potential. In the case of high performance stainless steel pumps and valves, this forecast will guide Engineering and R&D efforts. In the case of general performance stainless steel pumps and valves, the forecast will guide manufacturing investment.

Due to the Russian invasion of Ukraine, and the Chinese lockdown, the stainless steel pumps and valves markets are rapidly changing, making continuous forecasts necessary.

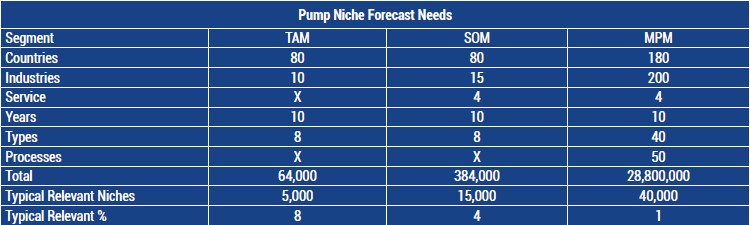

The most profitable market can be a large number of small niches. IDEX is an example of a company with close to 30% EBITA and fairly large volume. However, the company consists of a number of independent divisions each pursuing a unique niche. Identifying these profitable niches requires much more detailed market analysis than is typically pursued by stainless steel suppliers. By understanding profitability variables for the pump and valve suppliers, the strategy for sales of the stainless steel can be appropriately tailored. Figure 3 is an example for pump niches.

There are various levels of forecasting available. The Total Available Market (TAM) includes all of the opportunities, whether they can be serviced, and are obtainable, or not. The Serviceable Obtainable Market (SOM) reflects the market which can be pursued. However, much of this market will not be very profitable. A much more detailed forecast is needed which analyzes all the niches and determines where the most profit can be achieved.

The ability to calculate any of 128 million niches relies on top-down, bottom-up, and horizontal iteration. It would be prohibitively expensive to conduct for just one category such as stainless steel valves. But, if the expense is diluted by including forecasts of equipment using valves plus complimentary air, water, and energy products, the cost for the analysis is reduced.

A typical example would be a company of medium size who would be involved in 5000 niches or 8% of the TAM. With further segmentation in SOM, the number expands to 15,000, and the percentage drops to 4. The most profitable market may involve 40,000 niches or just 1% of the total. If competitor market shares and sales quotas for territories are also included, the number could rise significantly. This effort will be relatively expensive, but as part of an evidence based sales program, the benefits far outweigh the costs.

Evidence Based Strategy

The stainless steel material performance is just one factor in the overall determination of cost of ownership based on evidence. This evidence includes understanding the process needs in each industry. Once the most profitable market is determined, the evidence can be used to validate the lower total cost of ownership.

The sequence to the evidence gathering process is as follows:

1. Raw data,

2. Predicate evidence,

3. Disputed evidence,

4. Claims based on the evidence,

5. Rebuttal to counter claims made by competitors.

Suppliers have the opportunity to accomplish steps 2-5 in advertisements, magazine articles, exhibition activities, white papers, and webinars. It is not enough to prove the lower total cost of a stainless steel pump or valve, it is also necessary to convince the customers with solid evidence.

This is a challenge, but a rewarding one with the potential to greatly increase revenues and EBITA.

References

1 Stainless Steel: World Markets published by the McIlvaine Company.

Bob McIlvaine is the CEO of the McIlvaine Company, which publishes Industrial Valves: World Markets. He was a pollution control company executive prior to 1974 when he founded the present company. McIlvaine oversees a staff of 30 people in the U.S. and China. http://www.mcilvainecompany.com

Bob McIlvaine is the CEO of the McIlvaine Company, which publishes Industrial Valves: World Markets. He was a pollution control company executive prior to 1974 when he founded the present company. McIlvaine oversees a staff of 30 people in the U.S. and China. http://www.mcilvainecompany.com