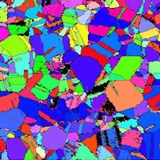

This weeks article, EBSD analysis and hot tensile properties of pulsed current gas tungsten arc welded super 304h austenitic stainless steel joints (Part two of two), talks about the need to increase the efficiency of the power plants, and achieve reduction in CO2 emissions can be attained by increasing the parameters of steam cycles.

Super 304H is capable of operating in steam temperatures of about 600°C, with excellent corrosion resistance and creep, the article explains. Super 304H, with the addition of 2.3 to 3 (% wt) of Cu, results in increased creep strength of the alloy, offered by the fine, stable, coherent Cu-rich precipitates, evolved during exposure to creep conditions.

For the full article, please email Catarina Muia at c.muia@kci-world.com for the article PDF.

Image courtesy of the U.S. Department of Energy