For nearly 150 years, Bonney Forge has remained at the forefront of U.S. manufacturing by producing high-quality forged steel fittings, valves, unions, branch connections, and specialty components. Operating out of two state-of-the-art facilities in Pennsylvania and Texas, the company is one of the few in the industry that maintains a fully domestic, vertically integrated supply chain. This capability – manufacturing entirely within the United States – sets Bonney Forge apart in a global market often subject to price volatility, supply disruptions, and shifting trade policies. Stainless Steel World spoke with Ramon Mohammed, Director of Business Development, and Paul Heald, Vice President of Product Engineering, Specialties and China Operations at WFI Bonney Forge, to learn more about the company’s operational strengths, commitment to American manufacturing, and vision for the future.

By Joanne McIntyre, Stainless Steel World

Fully Integrated Manufacturing for Complete Control

Bonney Forge’s forged fittings manufacturing model is built on vertical integration – design, forging, machining, heat treatment, testing, and assembly all take place inhouse. According to Paul Heald, this model is increasingly rare in today’s market.

“While many companies began outsourcing their forging needs decades ago, we’ve deliberately chosen to maintain full forging capabilities at both of our U.S. facilities,” he explains. “This means we’re not dependent on third parties to meet our quality standards or timelines. Customers know that when they buy a Bonney Forge fitting, it has been engineered and produced entirely under our control – from start to finish.”

This end-to-end production model not only improves consistency and traceability but also strengthens Bonney Forge’s ability to deliver specialty products and respond quickly to customer needs.

Tariff-Proof, Market-Resilient Operations

In an era of global supply chain instability, Bonney Forge’s domestic production model has become a major strategic advantage. Recent U.S. tariffs on imported raw materials and fittings have sent many manufacturers scrambling to secure inventory and manage cost increases. Not so at Bonney Forge.

“Because our raw material sourcing program emphasizes domestic suppliers, we forge our fittings in the U.S., we’re shielded from the price fluctuations and delays that have disrupted our competitors,” says Mr. Heald. “We’re not exposed to sudden market shifts in foreign steel or alloy supply. That means we don’t have to raise our prices, and our customers benefit from consistent pricing and delivery.

In fact, Bonney Forge has seen a boost from these dynamics. “Tariffs have actually helped us,” Mr. Heald continues. “While others struggle with uncertainty, our customers know exactly what they’re getting—on time, at the agreed price. We’re not reacting to market chaos; we’re setting our own course.”

Ramon Mohammed agrees. “Many people assume all manufacturers are equally vulnerable to market fluctuations. They’re surprised – and pleased – when they find out that we forge in-house and focus on utilizing U.S. sourced material. That kind of domestic integration is rare in the fittings industry today.”

U.S. Facilities Optimized for Performance

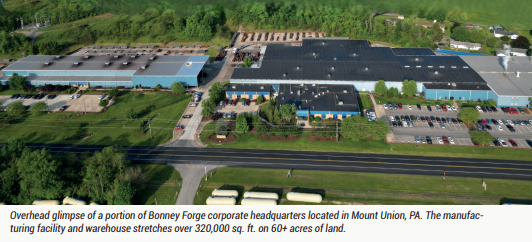

Bonney Forge’s manufacturing network includes two key production hubs: its highly automated headquarters in Mount Union, Pennsylvania, and WFI, its versatile facility in Houston, Texas.

“Mount Union specializes in small-diameter fittings made from a wide variety of materials, and is home to advanced automation technology that we’ve customized to our exact specifications,” explains Mr. Mohammed.

“WFI handles a broad spectrum of fittings, including large-diameter and specialty items, and works with over 100 different alloys.”

This dual-facility model allows Bonney Forge to scale production, diversify product offerings, and maintain tight quality control. Between the two plants, the company is capable of producing fittings in carbon steel, stainless steel, and an extensive array of exotic alloys.

Advanced Automation and Quality Assurance

As one of the largest forged steel fitting and valve manufacturers in the world, Bonney Forge places a high priority on automation, process control, and continuous improvement.

“Our facilities are built around custom-engineered automation and manufacturing systems designed specifically for our products,” says Mr. Heald. “That level of precision allows us to consistently meet the stringent requirements of ISO 9001, ASME B16.11, MSS SP-79, and MSS SP-83.”

In-house heat treatment, testing, and tooling development further reinforce quality. Bonney Forge doesn’t outsource any part of the production process. “We have full internal control over everything – from raw material handling to final inspection – which is how we consistently deliver on quality,” he adds.

Serving Critical and Emerging Industries

Thanks to this consistent quality and traceability, Bonney Forge is an approved supplier to many of the most demanding sectors, including oil and gas, nuclear power, and petrochemical processing.

“In the last six months, we’ve seen increased demand from energy and power generation projects, particularly those that prioritize domestic sourcing,” notes Mr. Mohammed. “Clients in these industries recognize the reliability of having fittings manufactured in the U.S.”

W.F.I., in particular, is certified for the nuclear industry and has manufactured fittings in over 100 alloys. “We’re optimistic about future demand, especially as investment accelerates in next-generation technologies like small modular nuclear reactors,” adds Mr. Heald.

Bonney Forge is also well-positioned for growth in emerging sectors such as hydrogen production, HF alkylation, wastewater treatment, mining, and battery recycling. “These applications require precision-engineered stainless steel fittings with proven performance – and that’s where we excel,” he says.

Inventory Depth Drives Responsiveness

To support fast lead times and mitigate supply shocks, Bonney Forge maintains extensive inventories across both its U.S. locations.

“Our Mount Union facility holds millions of dollars in inventory – literally millions of dollars of fittings on the shelf, ready to ship,” Mr. Heald explains. “This level of preparedness is unmatched in the industry and enables us to fulfill urgent orders without delay.”

By maintaining a robust supply of stainless steel and specialty alloy fittings, Bonney Forge has been able to capture new business in recent years – particularly from customers seeking U.S.-manufactured alternatives. Its inventory strategy also functions as a critical buffer during periods of raw material price volatility or sudden demand surges.

The Houston facility carries raw stock in over 60 alloys and performs forging, heat treatment, mechanical testing, and non-destructive evaluation (NDE) entirely on-site. “We control the product from billet to final inspection,” Mr. Heald emphasizes. “That’s the kind of reliability our customers are looking for.”

Comprehensive Product Portfolio

Bonney Forge manufactures a wide range of forged fittings and branch connections, all designed, produced, and tested in the United States. The standard product line includes elbows, tees, crosses, reducers, caps, and unions—available in a broad array of materials, pressure ratings, and sizes up to 4 NPS and beyond.

A signature product category is its line of highperformance Olets® branch connections, including Weldolet®, Sockolet®, Thredolet®, and others. These fittings are widely used for modifying existing pipe systems or building new configurations with minimal downtime.

Among the most notable is the Sweepolet®, an integrally reinforced, contoured branch connection designed for superior fatigue resistance and low stress intensification. “The Sweepolet® is welded into the pipe, not just onto it, which helps it absorb acoustic energy and reduces cyclic fatigue,” says Mr. Heald. “That makes it the go-to solution for high-demand sectors like LNG.”

Every Sweepolet® is engineered to accommodate specific stress and vibration concerns. “We apply detailed engineering analysis to ensure the fitting enhances—not compromises—the performance of the pipeline,” he adds.

Fast Track Emergency Services

Recognizing that some projects can’t wait, Bonney Forge offers a Fast Track service for urgent orders. Available 24/7 nationwide, this program ensures that critical fittings can be delivered in as little as four to ten weeks.

“Fast Track gives our customers peace of mind,” explains Mr. Heald. “When a project hits a snag or an emergency arises, they know they can count on us to deliver the required parts – accurately, quickly, and with full documentation.”

This service is particularly valued by EPC contractors managing complex timelines and large-scale infrastructure developments.

A Legacy of Leadership and Innovation

Since John Leone acquired the company in 1984, Bonney Forge has remained focused on customer satisfaction, operational excellence, and long-term innovation.

“Under Mr. Leone’s leadership, we’ve maintained a leading position in the market by continually investing in technology, facilities, and people,” says Mr. Heald. “We’re always looking ahead – but never lose sight of our foundational commitment to quality, service, and value.”

With a history spanning nearly a century and a half, and a production model rooted firmly in the U.S., Bonney Forge continues to set the standard for forged fittings manufacturing.