Allpax, a product brand of ProMach, has introduced a new corrosion inspection program to improve workplace safety and reduce the risk of premature pressure vessel failure due to corrosion in carbon-steel and 300-series stainless-steel retorts. The Allpax 40-point inspection is based on the American Petroleum Institutes (API) 510 standard for certified pressure vessel inspection.

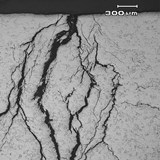

Retorts have an internal environment of high temperature and pressure created by steam, water, and oxygen. When excessive harmful chloride ions are present inside, or even on the outside of the retort, the ions act as a catalyst for starting and accelerating corrosion in stainless steel during the retort cycle. Unless steps are taken to identify, reduce, or eliminate the causes of corrosion, batch retorts may have their service lives cut short, which results in production disruptions and the need for early replacement of corroded vessels. There are associated worker safety issues from corroded sections as well. Allpax has written a white paper on this topic, understanding the Causes of Stainless-Steel Corrosion in Retorts and Practical Steps to Prevent Corrosion.

The Allpax inspection is a non-destructive examination of American Society of Mechanical Engineering (ASME) installed pressure vessels per API 510 certified inspector guidelines. The inspection includes a total of 40 evaluations within the following focus areas:

Quick opening door evaluation and inspection

Internal vessel shell structural evaluation

External vessel shell structural evaluation

Water sample evaluation

On-stream inspection points

Visual damage assessment, including images of problem areas

Current state of quality assurance/quality control (QA/QC) programs

Based on the examination, Allpax provides a corrective action plan to help ensure that the integrity of the pressure vessel meets or exceeds code requirements. As required, the corrective plan includes:

ASME repair plan along with hydrotest

Identification of damaged parts needing replacement and recommendations for spare parts to be held in inventory

In collaboration with the customers water treatment supplier, offer suggestions for altering the water chemistry

Requirements for re-rating the pressure vessel based on corrosion damage

Recommendations on utilizing corrosion coupons for future monitoring

Recommended intervals for follow-up inspections based on 40-point findings

Allpax has the intimate knowledge of retort construction, operation, and water chemistry that generalist pressure vessel inspectors lack, says Eric Hanrahan, Allpax General Manager. Our goal with this new initiative is to evaluate the retort and then chart a course leading away from corrosive conditions.

Press release and image courtesy of Allpax