Recognized as Americas Greenest City, Grand Rapids, Michigan, has introduced the initiative of a biodigester, which will convert food, to waste, to energy, and will include stainless steel hardware and corrosion-resistant materials in the construction.

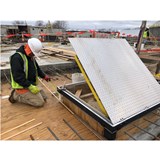

The USD$57 million biodigester is expected to be fully operational by the beginning of 2020, and will require pumps and mechanical equipment to power the biodigester. Nineteen products from Bilco Co. have been selected, including floor doors and roof hatches, which will allow workers access to equipment when the biodigester becomes operational. The biodigester, which will play an important role in Grand Rapids effort to develop 100% renewable energy to power city buildings by 2025, will include eight 4×4 roof hatches with safety railings on the roof exterior, and 11 floor doors of various sizes, including some with drainage. The city expects gas produced by the project will generate 60% of the electricity needs for the citys wastewater plant.

The safety grate provides a permanent means of fall protection. It includes a safety-yellow powder coat paint finish, and stainless steel hardware for corrosion resistance. Bilco, which has been manufacturing specialty access products for more than 90 years, can install grates on doors prior to shipment. Retrofit kits are also available for field installation.

The Grand Rapids system revolves around three tanks with a capacity of 1.4 million gal. Two tanks will be used for municipal biosolids. The other tank is an anaerobic membrane bioreactor that will quickly reduce organic waste. Electricity production from the biodigester is expected to offset the costs of the investment, and will help keep consumer rates steady.

Image courtesy of Eric Sawatzki, Water & Wastes Digest