In part two of this interview, Stainless Steel World Americas had the opportunity to speak with Garrett Borrow about what hopes he has for the future of stainless steel manufacturing.

By Brittani Schroeder

Projects and challenges

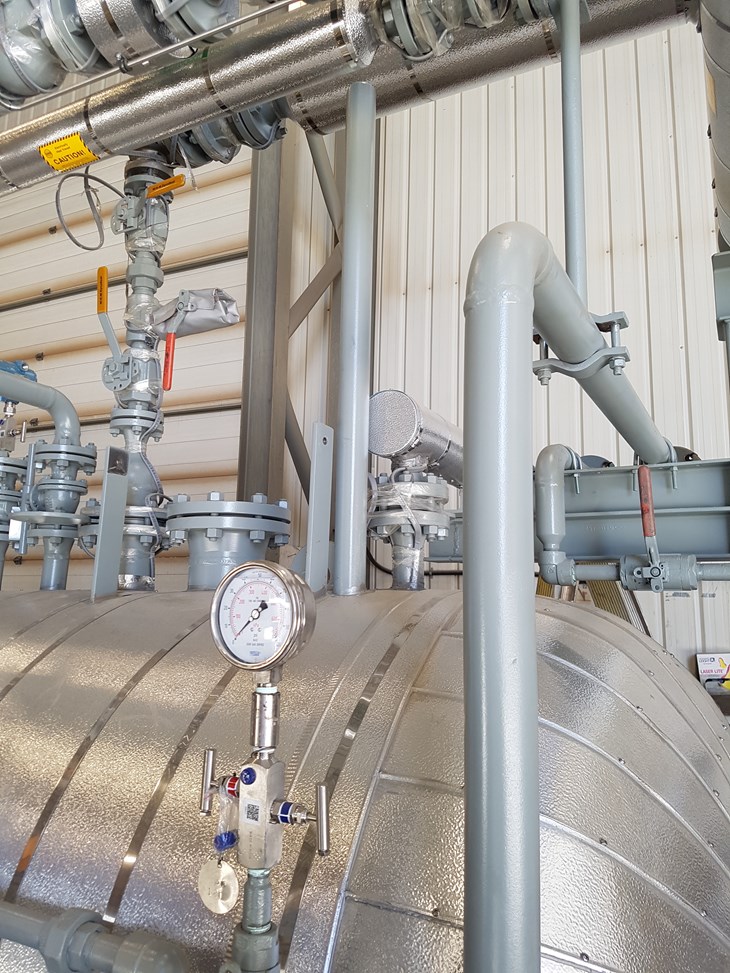

Borrow and his team typically have five to seven large projects on-the-go at all times. As they are located in Alberta, their projects are primarily for the oil and gas industry, and typically consist of oil field equipment to be used throughout the province. “We are also making modular units that we ship internationally – New Zealand and Romania, just as examples,” says Borrow.

There are many challenges Borrow and his team face while working on their various projects. “My biggest challenge is being a stop in flow, but there are a ton of other challenges we encounter every day,” he relays. For Borrow, a common challenge he and his team come up against is obtaining materials and the supply chain. This problem has become increasingly worse since the COVID-19 pandemic caused mill and manufacturer closures.

As an inspector, Borrow works within a three-millimeter tolerance. What does this mean? “Even if the pipe is 17 meters long, it needs to be within 3 millimeters (mm) of the dimension on my drawings, or else it is unacceptable,” he explains. “This can get tricky, because when you connect 30 17-meter-long pipes together, and if I accept 3 mm on one section, another 3 mm, and another and so on, suddenly we are out half-an-inch, and it becomes a problem.” For Borrow, running into a problem like this is a big challenge as it requires that the team to go out to the site and perform repairs which could have been avoided if they were caught in the shop. “But sometimes it is not feasible to catch right away,” Borrow states.

Materials and supply lead times

Borrow has seen and worked with a lot of different materials during his career. Typically, he and his team work with mild steel, but they have seen a lot of stainless steels as well. The stainless steel systems Borrow and his team work on are typically smaller in size, and include a wide range of stainless grades.

For the majority of Borrow’s projects, the material selection process is dictated by the project’s requirements. “The company has a team of people dedicated to finding us the correct material, ensuring it will arrive within our schedule, and auditing suppliers and making sure they are up to par for our projects,” Borrow relays. The shop where he and his team are located is in the East Shepherd Industrial Park in Calgary, AB, which means that sometimes they can obtain materials from nearby companies. At other times, the clients bring in their own materials that have already been sourced and obtained.

In regard to obtaining supplies, lead times can delay a project, and this has happened to Borrow on several occasions. “How far out we order materials and parts depends on the project’s deadline, and it depends on what we are ordering,” he comments. “If we need to order specialty materials, or European fittings, it can take upwards of a month or more for shipping. It will also depend on the size of the part, because you cannot express post a component or material that is 1,200 pounds,” Borrow explains.

Working with stainless steels

Stainless steel has been a requirement for many of Borrow’s projects, which has allowed him learn about the pros and cons of the material. “Stainless steels have a lot of benefits – corrosion resistance and long-term durability, for example – but there are also manufacturing downsides that I hope will be improved in the future,” Borrow says.

Stainless steel has a high thermal expansion rate, which means it will expand when heat is applied. Once it has expanded, it will not shrink down to the size it was before the heat was applied. This makes it difficult for welders, because the welding process requires the application of heat to the material.

Keeping stainless steel straight is one of the team’s biggest issues when working with the material. “We also have to deal with stainless steels as they harden. When stainless steels are heated and cooled in a certain way, sometimes it will harden, and then, like glass, it becomes brittle. In general, it is best to not rework stainless steels,” Borrow explains. “Overall, the pros are on par with the cons, and I am looking forward to when there are no more cons to speak of in relation to stainless.”

Welded valves

On a day-to-day basis, Garrett Borrow often works with valves and valve fittings. “We also see some valves coming through our shop. Anything welded will come past me or one of the other floor inspectors, so we have seen a lot of valves in our work,” Borrow relays.

The most common problem experienced with the valves are leakages. While most problems are caught prior to the inspection stage, there is the odd time that an issue will go unnoticed. “I typically just look at the valve’s class, rating, material, etc., to make sure it all looks good. I might even cycle it once to ensure that it turns properly. Once the valve is welded on and sent down the line, the biggest problem is leaking, and that is why we run the hydro test. We do not want any leaky valves!”

Sharing industry experience

As veteran engineers start retiring, the urgency and importance for the younger generation to learn from their experiences is paramount. “When I started at my first company, the ‘Mom and Pop’ shop, the owner’s son had just left engineering school. He entered the company and he learned everything he needed to from his dad, who had been in the industry for many years,” relays Borrow. It is Borrow’s belief that the knowledge gap in the industry works both ways. “The new engineers graduate from school with the knowledge of how to use new technologies and work the computers, while the older generation of engineers are able to whip out a piece of paper and tell the younger generations about how they could be wrong. It is really interesting to see.”

Borrow believes that over the next 15 to 20 years, as more engineers retire, younger engineers will need to step up and learn as much as they can from the older generations before they go. “We need to soak up everything we can and learn from their experiences before we lose them from the industry. What we learn in school is the ‘industry ideal’, and that is not what happens in the real world. We need to learn firsthand from those who have experienced the industry for decades.”

Borrow has learned a lot from his mentors and older inspectors throughout his industry experience. “I feel like a lot of people say there is a knowledge gap because the older generation of engineers do not want to share their secrets, but I think the real problem is the younger engineers not asking them to share. It is our responsibility to learn from them; we might need to give them a push to get started,” Borrow relays.

Final thoughts

Borrow’s hope for the future is a shift into new industries, which will bring in new types of projects. “We are really focused on the oil and gas industry, which makes sense because of where we are geographically located, but I think in the next two to three decades, it would be great to start branching out. The oil and gas industry will always be around, but we may see a reduction of oil in favor of other emerging technologies, and we need to be ready for that shift,” says Borrow.

Garrett Borrow also shared some advice to new engineers by saying, “Take a few minutes, get out onto the shop floor, and try to meet a welder. Those welders are really nice people, and they will be able to show you a totally different side of the industry that you had no idea about. There is so much more to learn than what you have seen on paper, and we are willing to teach you.”