Tekna, a company that produces 3D printing powders by gas plasma atomization, has signed a Memoranda of Understanding with Luxembourg steel specialist, Aperam.

The companies have agreed to co-develop spherical metal-powdered feedstock for use in 3D printing and metal injection moulding (MIM).

This news follows Teknas $5.5 million investment in the expansion of production facilities in Sherbrooke, Québec.

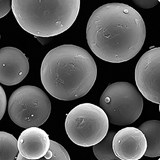

Gas plasma atomization at Tekna ensures the production of powders with a controlled grain size and sphericity with a high level of purity. For additive manufacturing (AM) specifically, the range of powder includes Ti64 titanium, Tungsten Carbide, Tantalum, and Molybdenum, a common addition to steel and stainless steel alloys. Aperam, on the other hand, produces steel and stainless steel in bars, strips, wire rods and plates.

Since the expansion of its facilities in Quebec, Tekna is on track to increase the production of its powdered products to more than 1,000 tonnes per year.

Image courtesy of Tekna