By Catarina Muia

Founded in 2013, SciAps aimed to construct the world’s first handheld analyzer to measure carbon in stainless steels and other CRAs; a tool the industry had been in search of for the past 40 years. While there have been analyzers that could do this job, they have not been handheld. “We wanted to take on this challenge and in mid-2017 we introduced the first such unit that meets the industry requirements for carbon testing in alloys,” says Sackett.

“Steels are used for so many different industries and the problem is they all look alike. It is so easy to mix up a low-carbon steel with a mid- or high-carbon steel, but the amount of carbon in the material determines the strength. It also affects how you weld the material; if you do not weld something properly the application will fail, which can have catastrophic results.” In the world of stainless steels, low-carbon stainless steel (a measurement of 0.03% carbon content or lower) is typically specified for projects to obtain a certain level of corrosion resistance.

SciAps analyzers: LIBS and XRF

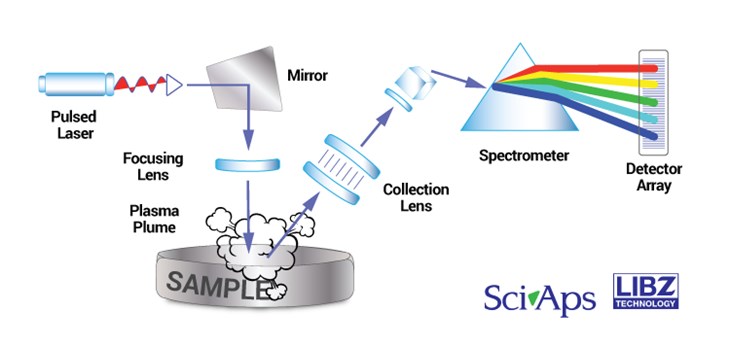

SciAps offers two different technologies. The first is the Laser-Induced Breakdown Spectroscopy (LIBS) technology, which has the ability to measure alloying contents, including carbon in stainless steels and other CRAs. The LIBS analyzer uses a pulsed, focused laser that fires at a sample with pulse energy, which then creates a plasma around the stricken area. Bound atomic electrons are stripped from the atoms, compromising the material. As the plasma cools, atoms recombine with electrons and in the process, emit light in the UV, optical, and IR regimes. While LIBS technology has been used for the past 30 years as a lab technique, it has been miniaturized into SciAps’ handheld analyzer.

Second is the X-Ray Fluorescence (XRF) technology. The XRF strikes a sample with an x-ray beam from an x-ray tube, which causes characteristic x-rays to become fluorescent from each element in the sample. A detector measures the energy and intensity of each x-ray, which is transformed into an elemental concentration using either a non-standard technique such as fundamental parameters or user-generated calibration curves. The element is identified by the element’s characteristic x-ray emission wavelength or energy. The amount of element present is quantified by measuring the intensity element’s characteristic x-ray emission.

“The XRF is a great analyzer to use on essentially any kind of alloy. We tell our customers to use the XRF because it measures the elements very fast, it is relatively easy to use, and it is very precise when analyzing the elemental content in most alloys. The only thing the handheld XRF cannot do is measure carbon content,” Sackett states. “If you want to measure the carbon content, you need the LIBS analyzer.”

In order to properly use the SciAps units, Sackett recommends plenty of experience and training, especially for the LIBS units. “Analyzing carbon is difficult because it is everywhere. It is in dirt, it is in oil, and it is in the air, so you need to be cautious,” Sackett stresses.

To begin using the LIBS unit, it must first be turned on and warmed up for around five minutes. During the five-minute warm-up period, the analyzer can be tested by taking any type of metal and running three to four tests. “This speeds up the warming process and brings the unit to a steady state temperature faster. You then would test a few standards to ensure the unit is in calibration. Once that has been done, the unit will be ready to go.”

When carbon testing a material, the material must be prepped beforehand. “Even if you are testing a shiny new piece of metal, you want to grind it because if someone has touched the material, it is guaranteed that there were oils on their fingers, which would then give you a high carbon reading,” Sackett explains. “Once the material has been grinded, it can be tested. The test itself only takes about three seconds, but you want to take around three tests, which will come to about 10 seconds to complete the entire process. At the end, you would then take the results from all three tests and average them out to get the final result.”

The importance of testing materials

Incorrect chemistry of an alloy is the most common reason that SciAps customers require the analyzers. “This can be caused by one of two things. Either some of the critical elements are not at high enough concentrations, or they are contaminant elements,” Sackett explains.

For example, the specification on nickel in a 316 stainless steel is 10% to 12%. However, some companies may purchase its stainless steel overseas to save money. “Nickel is expensive and can cost around USD $8 or USD $9 per pound. For these foundries to save money, they might only make the stainless steel with 8% nickel content instead of 10%,” he says. “If a foundry is making millions of tons of stainless steel, they can save a lot of money by cutting back on the amount of nickel going into the material. They might still call it 316 stainless steel, but the nickel content could be well below 10%.” Then, if an end-user takes that 316 stainless steel with a nickel content of less than 10% and applies it to one of their processes, there is a high chance that the application will fail.

In other cases, elements may be present that should not be. “In the refining industry, a lot of petrochemical processes that the steels are being used for require the concentrations of certain residual elements be below a maximum level,” Sackett explains. “For example, if carbon content is greater than 0.18%, the sum of nickel, chromium, and copper, altogether, must be less than 0.15%. More recently, the sum of niobium (Nb) + vanadium (V) must be less than 0.03%, with Nb and V both less than 0.02%. Anything higher and you will see steels that do not meet the correct requirements and cannot be used in certain petrochemical processes.” This issue has become a more frequent problem because steels are being made more from recycled materials today, as opposed to virgin iron ore.

For SciAps, the LIBS unit has been revolutionary, and has helped SciAps double the company’s sales revenue every year for the past four years. “Therefore, our biggest goal for 2020 is to double our sales again. It gets more difficult the bigger that number gets, but we do not mind the challenge,” Sackett expresses. “We just launched our new XRF analyzer, the X-550. It is the smallest, light-weight analyzer ever created.”

With a total weight of 2.8 lbs, the X-550 XRF delivers the small size, speed, and high precision, and can be used on all alloys. The analyzer is optimized for low atomic number measurement applications including sulfidic corrosion (low silicon), phosphorus and sulfur, and aluminum alloys, as well as for residuals analysis, per API 751 and 5L specifications.

“With the new X-550 XRF unit, I believe that our XRF sales are going to increase by a factor of three or four dozen. We expect to win a sizable portion of the XRF market in 2020 because of this new analyzer.”

The past four years have held success for SciAps, and Sackett could not be prouder of his team for it. “It is not often that you can say you are the first in the world to do something. When you can though, it is an amazing feeling. Our engineers have enabled us to achieve that from a technical side,” Sackett exclaims. “Our team of engineers succeeded in creating the handheld LIBS unit for carbon when around 10 other companies were unsuccessful. To me, that is such an impressive accomplishment, I am so proud of them for being the first to do this. As soon as one company does it, everyone knows it is possible. But we were the ones to discover that creating a unit of this size and with these specific abilities, is possible.”