Push and pull

When interacting with a perspective client there are two sales approaches that can be pursued. The first is a ‘pull’ approach; this is a strategy that aims to get the customers to come to the product. The second is a ‘push’ approach, in which a company or firm attempts to take its products to the consumers. It can be argued that it is far better for a prospective client to want to know how your stainless steel or other corrosion resistance alloy (CRA) will solve his/her problem (pull), than having to ask a prospect for his/her time to listen to your product pitch and then see if he has any current needs (push).

Collaboration strategies

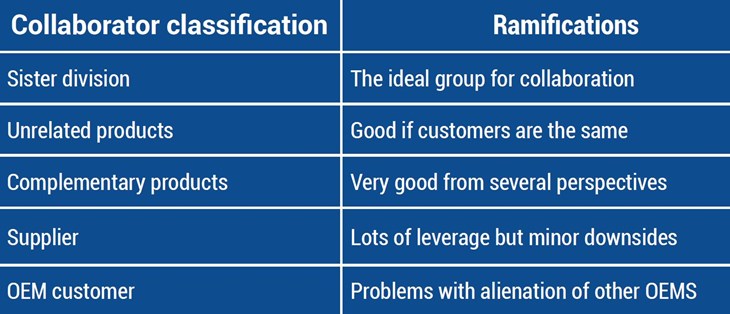

In all sales activities, knowledge of the applications and processes within a customer’s operation is of the utmost importance. Processes can involve air, water, gases, or petroleum liquids. Process steps can involve pre filtration, cooling, separation, drying, and evaporation. Suppliers of complimentary products can strengthen the process knowledge of each other.

Sharing with suppliers is good but only to the extent the supplier is willing to jeopardize the relationship with his other customers. You may receive good information from the one supplier but other suppliers will not be pleased. Sharing sales activity with OEM customers is ideal, except to the extent it could harm relationships with other OEMs.

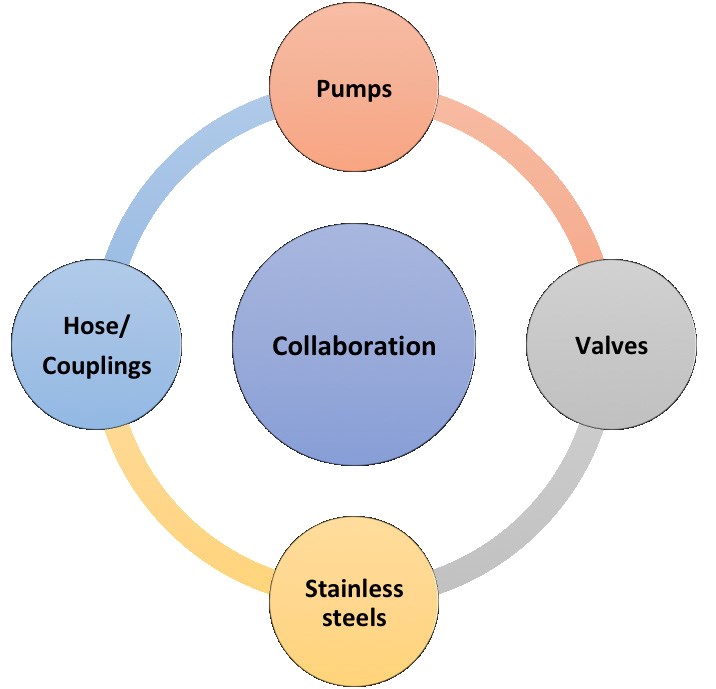

Complimentary products

Collaborating with the suppliers of complimentary stainless steel products has many advantages, which we will now explore. Stainless steels may be used in pumps, valves, and couplings. The material is likely to be incorporated throughout each of these systems.

Final thoughts

Due to the ever-evolving integration and use of the Industrial Internet of Things (IIoT), companies have the opportunity to not only share information on potential purchasers, but to collaborate on specific projects by approaching the client with solutions to their challenges. As a society that is progressively moving towards the new world of the Industrial Internet of Wisdom (IIoW), connecting in an organized way, with key suppliers of complimentary products will be paramount to leading a sale, rather than following a lead.

References

1. Stainless Steel: World Market published by the McIlvaine Company