Contrôle Mesure Systèmes has developed a software called Probus. Its main purpose is to collect information provided by N.D.T. equipment, in order to display signals, make a sorting decision and create inspection reports. On a non-destructive testing system, Probus is the decision-making center; it centralizes all the sensor data of the line and is able to control the actuators on the test bench. The software connects directly with the automation of the control bench, which it serves as a Man Machine interface.

The main purpose of the Probus software is to ensure the traceability of production with the creation of a product or batch inspection report. These reports can be presented by the quality services as proof of control and can include the list of defects detected with their position.

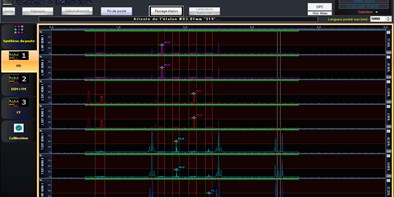

Alarm thresholds can be set on the software for each channel. When a signal passes the alarm, it is detected on the screen and the product is considered defective. The supervision software can handle several types of signals; U.S. signal, used in fault detection, U.S. signal used in thickness measurement, EC signal, etc.

Finally, Probus manages the good/bad sorting of products or/and control the marking system.

The Probus software can be combined with many other brands systems such as Ultrasound and Eddy Currents rotating heads, EC coil holders, magnetization/ demagnetization units and many others.

Because Probus is able to collect all analog signals, Contrôle Mesure Systèmes can easily integrate it on an obsolete bench and assure the revamping of the installation.

Courtesy of Contrôle Mesure Systèmes.