In theory, modern heat exchangers can be made from a wide range of materials, including copper, copper/nickel, aluminium, carbon steel, and stainless steel. In this article we examine why this is the case, as well as the major benefits of thin-wall corrugated tube heat exchangers made from stainless steel.

By Carmen Nicolás – Components Sales Manager, HRS Heat Exchangers

As with other aspects of heat exchanger design, the choice of construction material depends on a number of factors based on the end use. These include general considerations, such as thermal efficiency, cost and durability, and others which may be more specific to a particular situation, such as hygiene, cleanability, and corrosion resistance. In many cases construction material selection may relate to finding the best compromise, as the material with the best heat transfer may not be the most hygienic or easy to clean.

In the simplest terms, copper and copper/nickel alloys are likely to have the greatest thermal conductivity, while composite materials and ceramics have the lowest; much can be achieved with good heat exchanger design. This means that in practice, materials with slightly less thermal efficiency, such as carbon and stainless steel, will provide exceptionally good heat transfer in practice. This is why most heat exchanger manufacturers use some form of steel for the majority of their products.

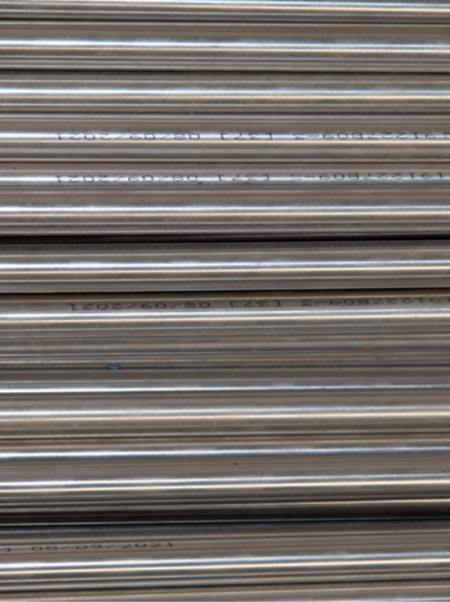

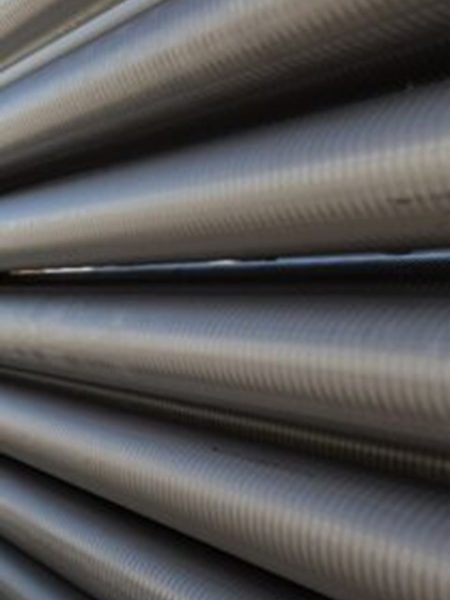

However, there are a number of advantages to choosing stainless steel over carbon steel, including using 316L stainless steel for the corrugated tubes in heat exchangers and 304L stainless steel for the outer shell.

Stainless Steel Versus Carbon Steel

316L stainless steel is an austenitic stainless steel alloy with low carbon content, meaning it is particularly resistant to corrosion and ideal for many key markets, including chemical processing, food (especially dairy) production, and pharmaceuticals.

To achieve similar levels of corrosion resistance using carbon steel would require much thicker tube walls. Not only would this provide lower heat transfer compared to thinner stainless steel tubes, but it would also prevent the corrugation of the tube and diminish the numerous benefits that can be applied to the overall heat exchanger design.

Conclusion

Because of the improved heat transfer, using corrugated stainless steel tubes results in a smaller overall footprint for the heat exchanger, meaning fewer or smaller modules to deliver the same or better performance compared to an equivalent model using straight carbon steel tubes. In addition, the smaller footprint and lighter construction of the modules and shell mean that ancillary and associated civil engineering costs are also lower. For example, the concrete used for pilings or foundations is a significant cost in many projects, so reducing the amount required not only saves money, but also accelerates the overall installation process.

About the Author

Carmen Nicolás joined HRS Heat Exchangers in 2019 as a Sales & Process Engineer. She is now the Components Sales Manager. Carmen obtained her degree in chemical engineering from Universidad de Murcia in 2015.

Carmen Nicolás joined HRS Heat Exchangers in 2019 as a Sales & Process Engineer. She is now the Components Sales Manager. Carmen obtained her degree in chemical engineering from Universidad de Murcia in 2015.