Steel production is both energy and resource demanding with a potentially significant environmental impact. The processes used rely heavily on coal and electricity which create greenhouse gas (GHG) emissions. In addition to carbon dioxide, steel plants release sulfur and nitrogen oxide along with particulate matter contributing to air pollution and subsequent health risks. Although airborne contaminants are a concern, large volumes of water are also consumed for cooling and scrubbing, generating wastewater containing several contaminants such as oil, suspended solids, and toxic compounds. Although modern steel plants have made vast strides regarding environmental impact, there are always areas of improvement as steelmaking is a critical target for improving sustainability and reducing industrial emissions worldwide.

By Michael Radicone, HTRI (corresponding author), and Doug Becker, HTRI

One of the most immediate opportunities for improving environmental performance in steel production lies in the optimization of wet flue gas scrubbers, which are central to emission control. These systems play a critical role in removing sulfur dioxide (SO2), particulates, heavy metals, and other hazardous pollutants from furnace and process gases. Regulatory oversight by the U.S. Environmental Protection Agency (EPA) imposes strict limits on SO2 and hazardous air pollutants, making efficient scrubber operation essential for compliance (U.S. EPA, 2021). Deployed across blast furnaces, basic oxygen furnaces, sinter plants, and coke ovens, scrubbers not only capture pollutants but also cool and condition flue gases, enhancing absorption efficiency while reducing thermal stress on downstream ductwork. Yet, despite their effectiveness, scrubber systems in heavy industry have historically struggled with fouling, scaling, and corrosion — chronic issues that erode efficiency and jeopardize regulatory compliance.

At the heart of this challenge is the associated heat exchanger, a component that is foundational to scrubber performance and, by extension, to both operational reliability and environmental sustainability.

Types of Heat Exchangers Used in Steel Manufacturing

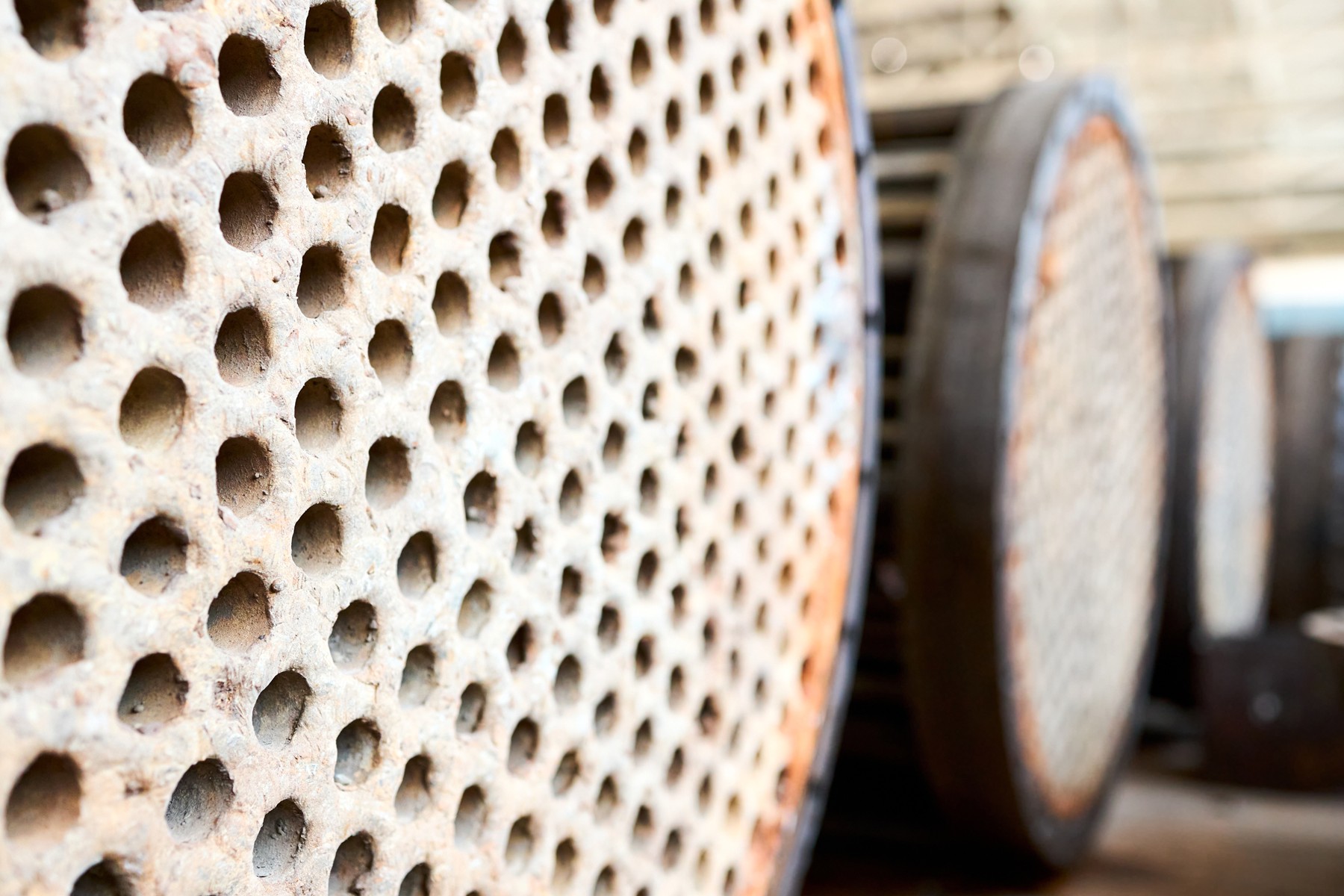

Commonly used in steel manufacturing, shell-and-tube heat exchangers are robust and capable of withstanding the elevated temperatures and pressures found in steel production.

Flue gas desulfurization (FGD) scrubbers are used to cool circulating slurry or process water to help ensure that adequate gas absorption efficiency is maintained and that equipment downstream in the process is protected from excessive thermal stress.

The tube bundle used is fabricated from varying metals such as stainless steel, titanium, or copper-nickel alloys, depending on the corrosivity and type of cooling water. Although quite durable, shell-and-tube exchangers, like any submerged component, are vulnerable to scaling and biofouling on the cooling water side. This is particularly evident in systems that use seawater or water containing elevated levels of total-dissolved-solids (TDS) or organics. Regular maintenance, water pretreatment, and antifouling technologies are required to maintain performance over long service cycles to provide adequate functionality.

Plate Heat Exchangers (PHEs)

In environments where a compact design or high heat transfer is required or desired, plate heat exchangers may be considered. PHEs are often applied in ancillary or supplemental cooling water systems, such as closed-loop cooling for rolling mills and blast furnace cooling circuits. PHEs can be gasketed, brazed, or welded depending on application and need for dismantling.

Gasketed designs are easier to disassemble for cleaning but may be less resistant to aggressive scrubber water when compared with welded or brazed alternatives. While plate exchangers offer excellent heat-transfer performance when using clean water, due to reduced flow space between plates, they may be more prone to fouling than shell-and-tube designs when feed water poses a high fouling potential. Although their use in flue gas scrubbers is less common, they remain valuable in parts of the plant where water quality can be more tightly controlled.

Fouling Mechanisms in Steel Scrubber Heat Exchangers

Fouling in heat exchangers has long been recognized as a persistent, arduous problem in all industrial applications, such as energy production, petrochemical, and, of course, steel production. It is defined as the undesired deposition of materials on heat-transfer surfaces. These may include inorganic precipitates such as minerals to organic matter and microbial biofilms.

Mineral or crystallization fouling occurs when dissolved salts such as calcium carbonate, calcium sulfate, and silica exceed their solubility limits during heat-transfer conditions that lead to scale formation on heat transfer surfaces. These deposits function as thermal insulators which reduce functionality. Furthermore, incursion into the flow stream restricts hydraulic flow, thus raising cooling water pumping costs, increasing energy demand, and undermining the performance of the scrubber system (Berce, 2021; Al-Haj Ibrahim, 2012). Biological fouling originates with microbial adhesion of fouling species and the development of biofilms on wetted surfaces. Besides also affected flow conditions, biofilms create a matrix that traps suspended solids, fosters under-deposit corrosion, and increases the potential of mineral scaling by providing nucleation sites (Flemming, 2002; Chemtreat, n.d.).

Impacts of Fouling

For steel manufacturing, as in many industries, the consequences of cooling- side fouling can be extensive. Reduced heat-transfer rates due to fouling can lower the cooling capacity of scrubber systems which diminishes the efficiency of SO2 absorption. Plants will have rising operational costs as pumps and auxiliary systems are forced to compensate for lost performance through the consumption of more energy than under clean conditions.

The presence of biological fouling deposits can lead to higher corrosion rates generated by microbial enzymatic activity which can weaken stainless steel and copper alloys. Naturally, whether treatment is based on a chronic or acute condition, the cleaning and replacement cycle for fouled heat exchangers is costly and disruptive, frequently requiring downtime that constrains steel throughput and reduces profitability (Chemtreat, n.d.; Müller-Steinhagen, 2011). The economic penalty in industrialized nations for fouling has been estimated in the hundreds of millions annually and reflects lost efficiency, corrosion damage, and maintenance burdens (Müller-Steinhagen, 2011).

Fouling Control Approaches

The mitigation and prevention of fouling in scrubber heat exchangers requires a multifaceted approach. Both mineral and biological fouling are insidious processes that begin immediately after a cleaned heat exchanger is brought online. Conventional strategies include the application of chemical treatments such as anti-scaling and biocides. This may be performed in conjunction with mechanical cleaning methods like disassembly, hydro blasting, or sponge-ball circulation. While effective, these methods are typically costly, potentially damaging, environmentally burdensome, and disruptive to plant operations (Al-Haj Ibrahim, 2012).

Interest in vapor infusion nanobubble technology has gained traction in use specifically on the cooling water side of marine and industrial scrubber heat exchangers through numerous successful applications. In these systems, chemical vapors are used to chemically catalyze the rapid formation of dense emulsions of nanobubbles. Nanobubbles disperse throughout the cooling water circuit, interacting with fouled surfaces by altering interfacial charge (Figure 1) and physically disrupting deposits. Field results from marine scrubber heat exchangers have demonstrated that vapor infusion nanobubbles for use in cooling water can clear existing fouling and maintain cleaner surfaces over subsequent operation. Vapor infusion nanobubble technology eliminates or minimizes the need for added biocides and reducing dissolved oxygen input that can accelerate corrosion (Radicone, 2024). For the water side of steel flue gas scrubber exchangers, the same principles suggest a promising role in suppressing both mineral scaling and biofilm formation, extending cleaning intervals, and lowering lifecycle costs.

Beyond the cooling side, due to ease of integration (Figure 2), there is also the potential to explore trial applications of vapor infusion on the flue gas side. In this scenario, nanobubbles dispersed into the gypsum slurry could not only help mitigate deposit formation on internal surfaces but may also improve pollutant capture by increasing gas-liquid interfacial area and enhancing SO2 absorption. Extending vapor infusion nanobubble technology to the gas-contact side of steel flue gas scrubbers represents an innovative opportunity to pair fouling prevention with enhanced environmental performance.

Conclusion

The cooling water side of heat exchangers in flue gas scrubbers represents both vulnerability and an opportunity in steel manufacturing. When fouling is allowed to occur and increase unchecked, mineral, and biological fouling can erode heat-transfer efficiency, raise energy and maintenance costs, and threaten compliance with increasingly strict emissions regulations. However, through a combination of traditional water-treatment programs and the possibility of novel technologies such as vapor infusion nanobubbles, the steel industry can significantly mitigate fouling risks. Ensuring clean, efficient heat exchange operation is thus not only a matter of plant economics, but also one of environmental responsibility and technological advancement.

References

- Al-Haj Ibrahim, H. (2012). Fouling in heat exchangers. In T. M. InTech (Ed.), MATLAB – A fundamental tool for scientific computing and engineering applications (pp. 57–96). InTech. http://dx.doi.org/10.5772/46462

- Berce, J. (2021). A review of crystallization fouling in heat exchangers. Processes, 9(8), 1356. https://doi.org/10.3390/pr9081356

- Chemtreat. (n.d.). Corrosion, scale, & biofouling control in cooling systems. Chemtreat Inc. Retrieved August 20, 2025, from https://www.chemtreat.com/solutions/water-essentials-handbook-chapter-corrosion-scale-and-biofouling-control-in-cooling-systems/

- Flemming, H.-C. (2002). Biofouling in water systems – cases, causes and countermeasures. Applied Microbiology and Biotechnology, 59(6), 629–640. https://doi.org/10.1007/s00253-002-1066-9

- Li, S., Lam, C. W. E., Donati, M., Regulagadda, K., Yavuz, E., Pfeiffer, T., Sarkiris, P., Gogolides, E., Milionis, A., Poulikakos, D., Butt, H.-J., & Kappl, M. (2023). Durable, ultrathin, and antifouling polymer brush coating for efficient condensation heat transfer. arXiv preprint. https://arxiv.org/abs/2311.13353

- Müller-Steinhagen, H. (2011). Handbook of heat exchanger fouling: Mitigation and cleaning technologies. Academic Press.

- Radicone, M. (2024, June 13). Nanobubble vapor infusion for heat exchanger fouling prevention. Heat Exchanger World. Retrieved August 20, 2025, from https://heat-exchanger-world.com/nanobubble-vapor-infusion-for-heat-exchanger-fouling-prevention/

- S. Environmental Protection Agency (EPA). (2021). Air pollution control cost manual, Chapter 5: Wet scrubbers for SO2 control (EPA/452/B-02-001). U.S. Environmental Protection Agency. https://www.epa.gov